Product Introduction

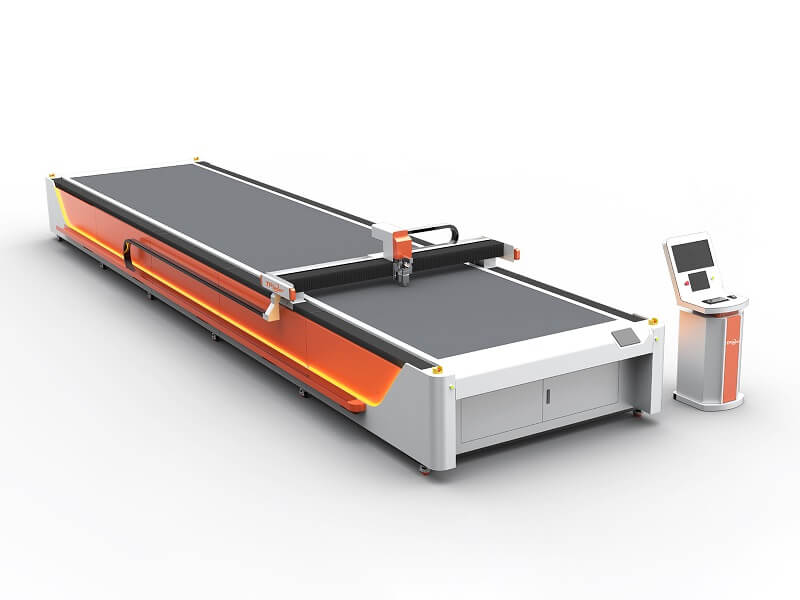

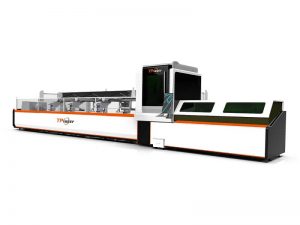

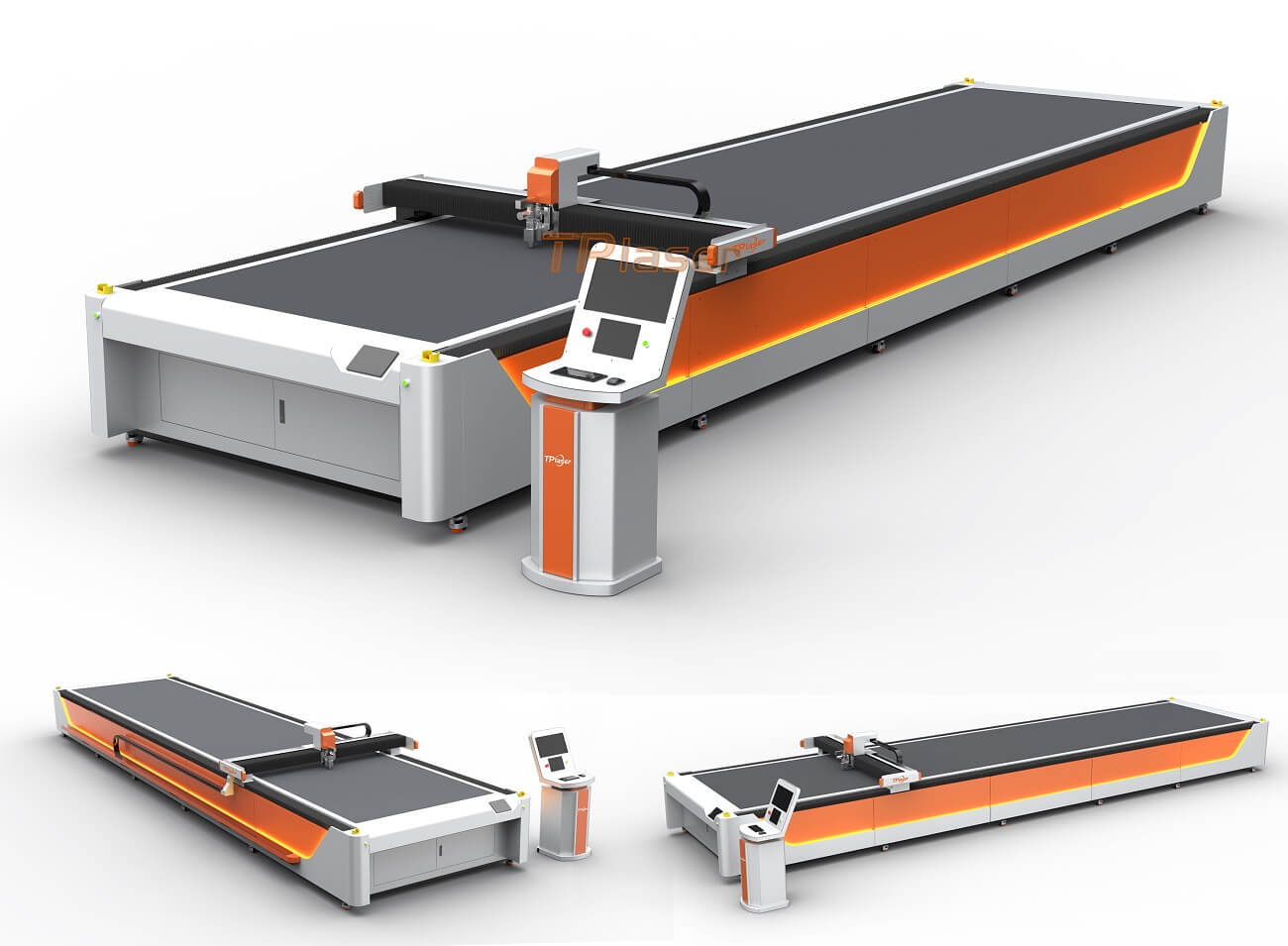

Buyer's ReviewsCNC leather oscillating knife cutter is a fully automatic cutting equipment of TPLaser for leather (artificial leather, real leather, recycled leather), luggage, shoes, clothing industry and other materials.

Demonstration Video

Product Descriptions

CNC leather oscillating knife cutter uses a vibrating knife blade for cutting, which is more accurate and environmentally friendly, and does not require manual patterning and drawing. It only needs to import the data into the computer to cut. Many manual cutting steps are eliminated. One piece of equipment can work continuously for 24 hours, maximizing the productivity.

Features of CNC Leather Oscillating Knife Cutter

1.The nesting and cutting are carried out simultaneously, which greatly improves the cutting efficiency;

2.No need for supporting punch and die, saving production cost and shortening production cycle;

3.CNC leather oscillating knife cutter is suitable for automatic leather cutting system of large size leather, cutting leather, artificial leather, rubber sheet, composite materials and other materials

4.Strong software compatibility; a variety of nesting tools integration, barcode database management functions;

5.The CNC leather oscillating knife cutter head tool adopts the vibrating cutter combination design; the cutting bed structure adopts the assembly line layout, which can feed the material in a cycle and save auxiliary man-hours; the cutting material has strong adaptability; the operation panel button layout is neat, the control software interface is simple, and the multi-layer feeding It can send four rolls of material at one time, equipped with motor and air clamp, accurate feeding, which is very convenient for factory operation.

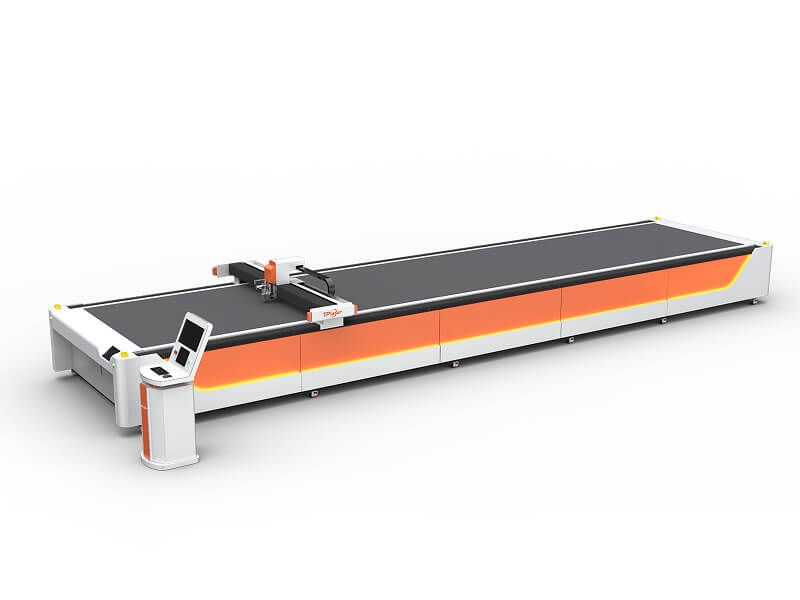

6.The one-piece aluminum platform adopts the principle of honeycomb composition, which is strong, anti-corrosion, durable, sound-absorbing and heat-insulating.

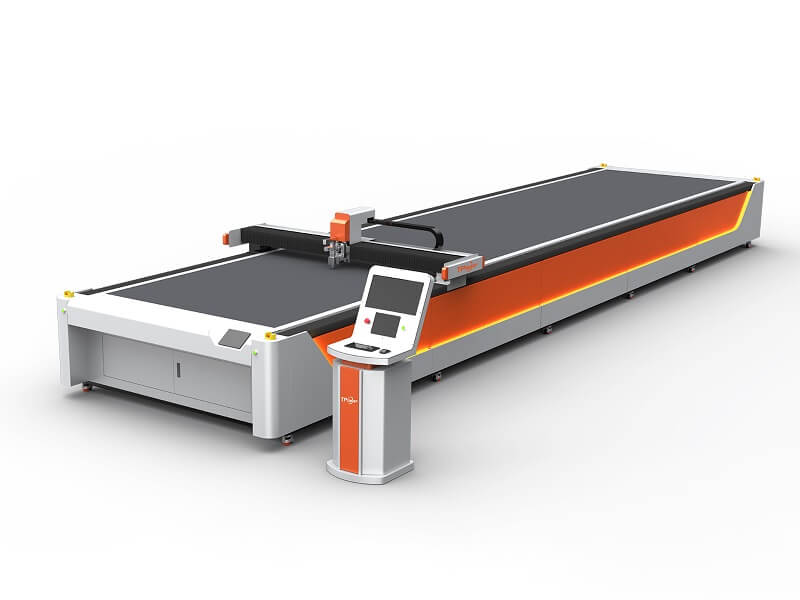

7.Each multi-functional cutting head of CNC leather oscillating knife cutter is equipped with: vibrating knife, line drawing pen. 2 pin holes, marking pins. It can cut leather of various thicknesses and ensure its quality, and it can also move flexibly and quickly, and it is easy and convenient to maintain

8.Shape projection effect. The high-definition projector can fully illuminate the work surface, even the hard-to-process leather can be completely illuminated. We use geometric design principles to allow the operator to analyze the material at close range without affecting the leather effect, and with the help of a projector, the operator can intuitively make layouts.

9.Laser projection, automatic grid-to-strip cutting;

10.The CNC leather oscillating knife cutterhas a unique fur clothing cutting scheme to ensure the integrity of the fur;

11.Software intelligent typesetting, material utilization rate is as high as 95%+;

12.2000mm/s high-efficiency cutting, 4-6 times the manual cutting speed;

13.Intelligent software compensation, the cutting accuracy is controlled within ±0.5mm;

14.The CNC leather oscillating knife cutterrealizes personalized customization and one-key cutting mode.

Specifications of CNC Leather Oscillating Knife Cutter

| Model | TPK1625/1825/2030 |

| Working size | Accept customization |

| Multifunctional cutting head | Replaceable vibrating knives, semi-penetrating knives, oblique knives, pressure rollers and other tools |

| Tool configuration | Various cutting tools, pressure wheel, pen, cross positioning laser |

| Security configuration | Highly sensitive infrared sensor (optional) |

| Moving speed | Up to 1200mm/s |

| Working speed | Up to 800mm/s (set according to different cutting materials) |

| Cutting material | EPS, foam, sponge, car floor seat cover, sofa cover, genuine leather, clothing fabric, corrugated paper, chevron board, kt board,etc. |

| Cutting thickness | Maximum 50mm (depending on different materials) |

| Material fixing method | High-power vacuum adsorption and intelligent partition |

| Repeatability | 0.01mm |

| Mechanical accuracy | 0.02mm |

| Transmission system | Steel wire timing belt, AC servo motor, linear guide |

| Control System | Dual 32-bit RISC core cpu + large-scale programmable logic array FPGA |

| Display method | Chinese and English LCD touch screen |

After Service of CNC Leather Oscillating Knife Cutter

1.We will supplyCNC leather oscillating knife cutter with training video and user’s manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

2.You can come to our factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

3.Our engineer will do a door-to-door instruction training service at your local site.