Product Introduction

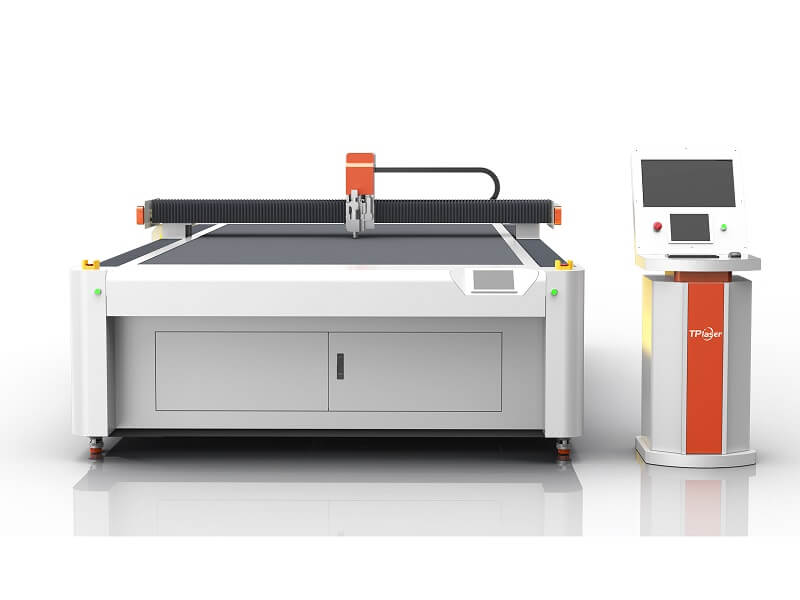

Buyer's ReviewsDigital fabric cutting machine can assist customers to process perfect works within a limited time and venue, and it is the best choice for intelligent cutting of flexible materials such as clothing fabrics. TPLaser provide professional vibrating knife cutting machine.

Demonstration Video

Product Descriptions

Digital fabric cutting machine equipment is suitable for cutting lace, modal, canvas, linen, cashmere, Oxford cloth, silk, chiffon, chemical fiber, wool and other materials, with fast speed, stability and high precision, whether it is single-layer cutting production or multi-layer cutting.

Digital fabric cutting machine is a modern cutting machine for cutting multi-layer materials with high precision. Its use completely eliminates all the degrees and points that must be mastered in the traditional manual cutting process, and the cutting speed is fast and the production efficiency is improved. Digital fabric cutting machine is a relatively widely used processing equipment in the cutting process of non-metal flexible materials. Because it has the unique characteristics of a multi-functional head, it is equipped with different tools and different cutting tools to cut different materials. It will also change with the change, It is more suitable to use a vibrating knife to cut leather sponge composite materials, and it is more suitable to use a pneumatic knife and a circular knife to cut fabrics, and a drag knife can be used to cut paper stickers.

Specifications of Industrial Digital Fabric Cutting Machine

| Model | TPK1625 |

| Working area | 1600*2500mm |

| Control system | Kinco touch screen control system |

| Positioning accuracy | ±0.01mm |

| Cutting Speed | 200-2000mm/s |

| Safety device | Infrared induction |

| Graphic format supported | DST,PLT, BMP, DXF, DWG, AI, LAS, etc. |

| Feeding method | Automatic feeding |

Advantages of Automatic Industrial Digital Fabric Cutting Machine

1.Digital fabric cutting machine is easy to operate, and the equipment has a self-developed cutting system. The novice can be employed after two hours of training.

2.Good cutting effect and high precision. Digital fabric cutting machine adopts Panasonic servo motor, with pulse positioning, positioning accuracy of ±0.01mm, and cutting without sawtooth and burr.

3.Material saving, the equipment adopts intelligent typesetting system, which can save more than 15% of materials compared with manual typesetting.

Applications of Digital Fabric Cutting Machine

Digital fabric cutting machine is suitable for a variety of materials, such as: corrugated paper, honeycomb board, cardboard, stickers, stickers, polyester fiber board, sound-absorbing cotton, PVC board, foam board, foam, carbon fiber, glass fiber, ceramic fiber , fabric, wire loop, leather, felt, carpet, rubber, kt board, etc.

Samples of Automatic Industrial Digital Fabric Cutting Machine

Precautions for Vibrating Knife Cutting Machine:

1.When moving the working table of the vibrating knife cutting machine, the moving speed should be correctly selected according to the distance from the workpiece to prevent collisions when moving too fast.

2.When programming, it is necessary to determine the correct processing technology and processing route according to the actual situation, and prevent the workpiece from being scrapped or cut off in advance due to insufficient processing position or insufficient edge strength.

3.Before wire cutting, it is necessary to confirm whether the program and compensation amount are correct.

Pay attention to observe and judge the processing stability of the vibrating knife cutting machine when starting the cutting, and adjust it in time if it is found to be defective.

4.During the processing of the vibrating knife cutting machine, it is necessary to check and supervise the cutting conditions frequently, and deal with the problems immediately.