Top Searches:

Warning: Undefined variable $categoryID in /www/wwwroot/tplaser.com/wp-content/themes/astra/functions.php on line 1237

Service

Laesr machines from TPLaser can be divided into the following categories:

Metal plate & pipe cutting machine

Automation laser cutting machine

Laser cleaning machine

Co2 laser cutting machine

Metal plate cutting machine

Fiber laser pipe cutting machine

Fiber laser welding machine

Laser marking machine

Inquiry Online: Our sales staff will provide suitable fiber laser cutter machine configuration according to the material and thickness you cut and your budget.

Make Quotation: We will offer to you with our detail quotation according to our consulted laser machines, with high quality and the affordable laser machine price.

Process Evaluation: Both sides carefully evaluate and discuss all the details of the order to exclude any misunderstanding.

Placing Order: If there is no doubt, we will send you the PI (Proforma Invoice), and then we will sign a contract with you.

Production: We will arrange the production as soon as receiving your signed sales contract and deposit. The latest news about production will be updated and informed to the buyer during the production.

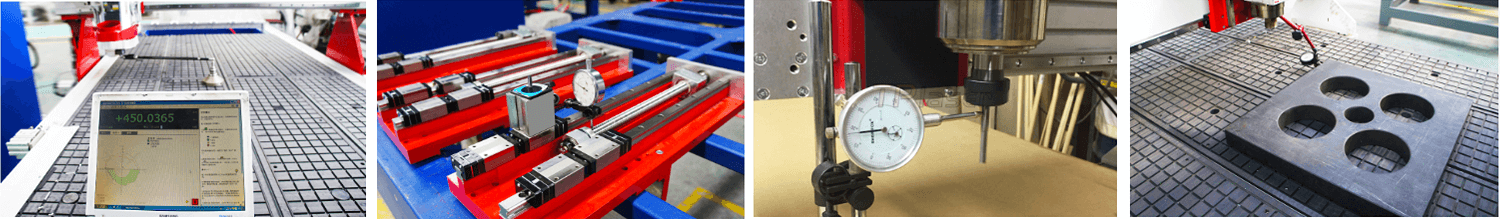

Inspection: The whole production procedure will be under regular inspection and strict quality control. The complete laser machine will be tested to make sure they can work very well before out of the factory.

Delivery: We will send video and picture of laser machine let you confirmation, after receive your balance payment, We will arrange the delivery as the terms in the contract.

Custom Clearance: We will supply and deliver all the necessary shipping documents to the you, and ensure a smooth customs clearance from your country customs.

Support and Service: We will offer professional technical support and laser machine service by Phone, Email, Skype, WhatsApp around the clock.

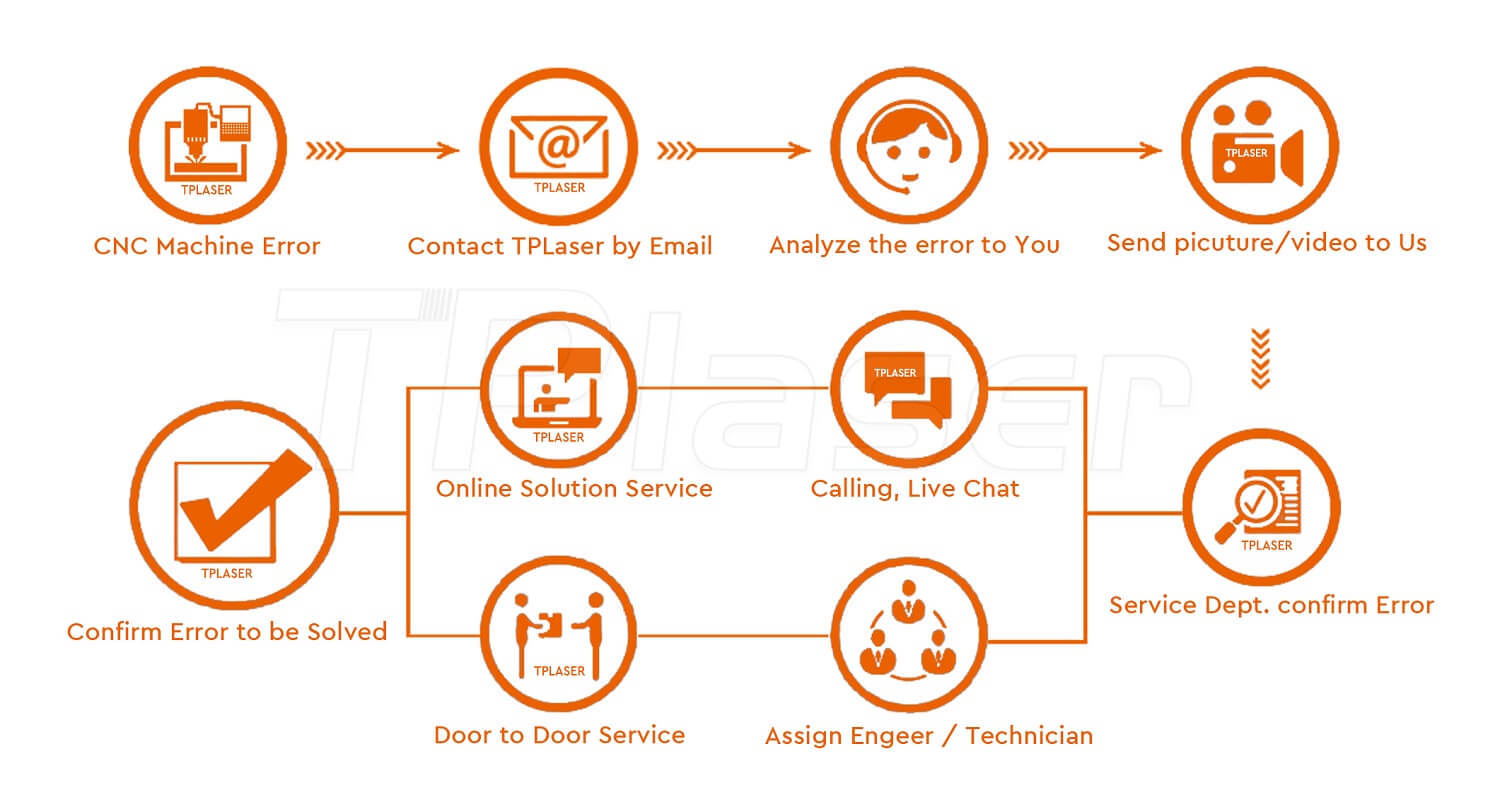

The TPLaser machine is easy to install and has good stability. However, if there is a problem, TPLaser will provide you with fast, appropriate CNC service and after-sales service for CNC repair. We are always on hand to provide you with a hotline service to correct interference through fast, qualified CNC service operations. Our English CNC engineering team provides Skype, video and telephone support for troubleshooting CNC machining centers.

The bed of the machine is the main reason that affects the accuracy. The manufacture of the bed is especially important. A good machine bed can be unchanged for 15-20 years. However, in the Chinese market, the processing technology of the bed is very different, and often some customers only pay attention to the price, not the quality, resulting in problems with the accuracy of the machine for a period of time. If you are a novice, please pay more attention! Here i introduce the processing technology of TPLASER machine bed to you as follows.

First, multi-temperature quenching of ductile iron; ductile iron can obtain high strength after isothermal quenching, and has good plasticity and toughness at the same time.

Second, stress relief annealing; due to the uneven wall thickness of the casting, in the process of heating, cooling and phase transformation, effect stress and structural stress will be generated. In addition, large parts are prone to residual stress after machining, and all these internal stresses must be eliminated. The usual heating temperature for stress relief annealing is 500~550℃, the holding time is 2~8h, and then furnace cooling (grey iron) or air cooling (ductile iron)

Third, high-temperature graphitization annealing to eliminate the white mouth of the casting; when the casting is cooled, white mouth often occurs on the surface layer and thin section. The white mouth structure is hard and brittle, with poor processing performance and easy to peel off. Therefore, annealing (or normalizing) must be used to eliminate white mouth tissue. The annealing process is: heating to 550-950℃ for 2~5h, then furnace cooling to 500-550℃ and then air cooling

Fourth, normalizing of ductile iron; the purpose of normalizing ductile iron is to obtain pearlite matrix structure, refine grains, and uniform structure, so as to improve the mechanical properties of castings. Sometimes normalizing is also the preparation of ductile iron surface quenching on the structure, normalizing is divided into high temperature normalizing and low temperature normalizing. The high temperature normalizing temperature is generally not more than 950~980℃, and the low temperature normalizing temperature is generally heated to the common folding temperature range of 820~860℃. After normalizing, four people are generally required to deal with it to eliminate the internal stress generated during normalizing.

Fifth, quenching and tempering of ductile iron; in order to improve the mechanical properties of ductile iron, generally castings are heated to 30~50°C above Afc1 (Afc1 represents the final temperature of A formation during heating), and then quenched into oil after heat preservation to obtain martensitic body tissue. In order to properly reduce the residual stress after quenching, generally, tempering should be carried out after quenching. The low-temperature tempering structure is tempered martensite plus residual bainite and spherical graphite. This structure has good wear resistance and is used for parts that require high wear resistance and high strength.

Sixth, chemical heat treatment; for castings that require surface wear resistance, oxidation resistance, and corrosion resistance, chemical heat treatment processes similar to steel can be used, such as gas soft chlorination, chlorination, boronizing, sulfurizing and other treatments.

The painting process will also affect the life of the machine. If one step is missing, the machine will rust and crack for a long time. If you are a novice and only pay attention to the price and not the machine painting process, I don’t think you can get a good machine. Here i introduce the technical requirements for the painting process (painting process) of TPLASER machine bed are as follows.

1.Before painting the machine bed, check the castings of the bed, use tools to trim the unevenness of the surface, and remove the dirt on the surface.

2. The machined bed casting must be rinsed or brushed with metal cleaner or clean industrial gasoline before painting to ensure that oil and other dirt on the surface are completely removed.

The primer should be applied evenly by brushing, spraying, or dipping. The primer must be fully stirred before use, and diluted to an appropriate year before applying.

3. The putty that fills the depression of the casting should be added with an appropriate amount of curing agent according to the product’s instructions for use, and must be fully stirred before use.

4. If vinyl perchloride is used to fill the depressions of the bed casting, each scraping should not be too thick. The thickness of scraping is generally about 0.5 mm. Each scraping must wait for the material to be scraped to dry before proceeding.

5. After filling the depression of the bed casting with perchloroethylene, it must be dry before grinding. After each grinding, the grinding slurry and dust on the surface need to be completely removed.

6. Use water grinding technology for grinding. In order to prevent the machine tool casting from rusting on the processed surface, it is necessary to use anti-rust water for grinding.

After grinding, if there is metal exposure, it is necessary not to brush the matching primer.

7. After the last putty is polished and cleaned, it is necessary to spray the second primer of vinyl chloride, which can improve the flatness of the paint film and improve the gloss of the paint film.

CNC machines sold by TPLASER are covered by a 24-month warranty from the date of shipment. CNC machines sold through resellers must be registered with TPLASER within 30 days of purchase to receive this warranty.

TPLASER guarantees that all CNC machines sold are new, do not sell used equipment, do not use counterfeit accessories, if there are defects in accessories and materials. We will repair or replace it free of charge. If an accessory is being returned or returned for repair, there must be sufficient packaging to ensure that no damage has been received in transit. If an item/part is determined to be damaged due to lack of maintenance, cleaning, or misuse/abuse, the customer will be responsible for the cost of replacement item accessories, as well as all associated shipping charges. The limited warranty does not apply to natural disasters, acts of terrorism, normal wear and tear, product failure due to lack of maintenance or cleaning, accidental damage, insufficient dust removal, etc.

It is certified that the guaranteed for free repairs up to 2 years from the date of purchase against assembly/manufacturing faults. This guarantee is in-valid under the following circumstances.

If the appliances is not used in accordance with the operational manual supplied by the company, or any misuse.

If the unit is damage after a fall, or a shock.

If dismantled, or tampered with any way.

Any fault occurred due to incorrect power supply.

Commercial use of Cambridge appliances will void the Guarantee.

Parts under warranty are carried by TPLASER and shipped by common carrier, FEDEX ground service or similar. Technical support for installing replacement parts is mainly provided by phone, whatsapp, email or online customer support. The labor required to install replacement parts is the responsibility of the user.

TPLASER is not responsible for damage or loss caused by the shipping company or other circumstances beyond our control. All claims for lost or damaged goods must be notified to TPLASER within twenty-four hours of delivery. Please contact our customer service department for more information. This warranty only covers new machines sold to the original owner. For warranty repair information, call +86-176-8668-3792.

Sure, we are China manuafacturers, we accept OEM and ODM as your requirements.

Two years on parts when get machine, 3 years for free repair. Life-time technical support.

When you get machine, there are English software, User manual and detailed installation & training video in the USB, also our engineer 24 hours technical online support by E-mail, Skype, Live Chat, TeamViewer software. also we supply oversea after-sale service.

We support T/T(Telegraphic Transfer), L/C(Letter of Credit), Western Union, Alibaba etc terms. and standard machine we can 15-20 working days can delivery.

If during warranty, we free change new one for you; After the warranty period, we provide it with our agent cost for you. and provide technical support for life.

Yes, our company have international certification system certificate: such as CE, FDA, SGS, ISO, FA, CO etc.