Top Searches: metal laser cutting metal laser cutter

Do you have an idea to DIY a metal sheet laser cutting machine or plan to buy a metal sheet laser cutting machine for stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, galvanized sheet , pickling plate, copper, silver, gold, titanium and other metal cutting? Reviewing the best metal sheet laser cutting machine guide in 2022, we provide customers with professional metal sheet laser cutting machines and services

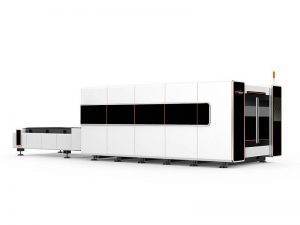

Metal sheet laser cutting machine is a device suitable for cutting various metal plates. It is capable of cutting metal through fiber lasers, connecting the fiber laser to the CNC machine tool, and making it through the operation and control of the system and motor and other equipment, cutting metal is more convenient and efficient CNC machinery equipment.

Metal sheet laser cutting machine can add fully enclosed cover and double exchange work table structure design. The fully enclosed design improves the safety protection performance and reduces the impact of the environment on cutting. The double exchange work table saves loading and unloading time and improves processing efficiency.

Laser cutting quality can be measured by the following 6 criteria.

1.Cutting surface roughness

2.Size of slag hanging on the incision

3.Trim verticality and slope

4.Cut edge fillet size

5.Stripe rear drag

6.Flatness

1.One piece of equipment can realize the four functions of leveling, feeding, cutting and unloading, breaking the traditional processing method.

2.Automatic assembly line, online cutting of coil material, saving labor and improving production efficiency.

3.The optical path is not restricted, the optical fiber transmission loss is small, and the processing range can be maximized.

4.Low maintenance cost: no laser working gas; optical fiber transmission, no need for reflecting mirrors; a lot of maintenance costs can be saved.

5.The software can realize the timely processing of various graphics and characters, which is simple and convenient to use.

6.Perfect smoke and dust removal system.

TPF2060

$28000 - $55000

TPF2040

$28000 - $45000

TPF2060

$13500 - $40000

TPF1325

$13500 - $22000

TPF1530

$13500 - $22000

TPF3020

$13500 - $22000

TPF3015

$13500 - $22000

We have used tplaser machine for a while. that's good quality. easy operate and no hear any problems. after sales service team very professional and reply in time. we are very appreciate it. Good profit to choose tplaser machines. i think we will buy another machine in the near future.

Everything about transaction was excellent. Great customer service and consistent communication. Got the laser faster than expected, and it works perfectly. Thank you!

TPlaser was great to work with. The sales person was professional. Her communication was quick and very knowledgeable. The fiber laser machine arrived in 2- containers and was packaged extremely well.

We have been too busy to do anything other than get the machine off the truck and into our building. Everything looks good and all the components are as ordered. Our sales Adam Zhang, was great to deal with during this whole process. We hope to have the machine in position, assembled and powered up sometime in the next couple of weeks.

Thank you very much. Production has started.the pipe is very good!

The machine is very good, we can use it to cut clothing cloth, not only can cut single layer or multi-layer, but also can be used to cut printed cloth. After using the machine, our efficiency is increased by three times, and we also save a lot of manpower and cloth, thank you.