Product Introduction

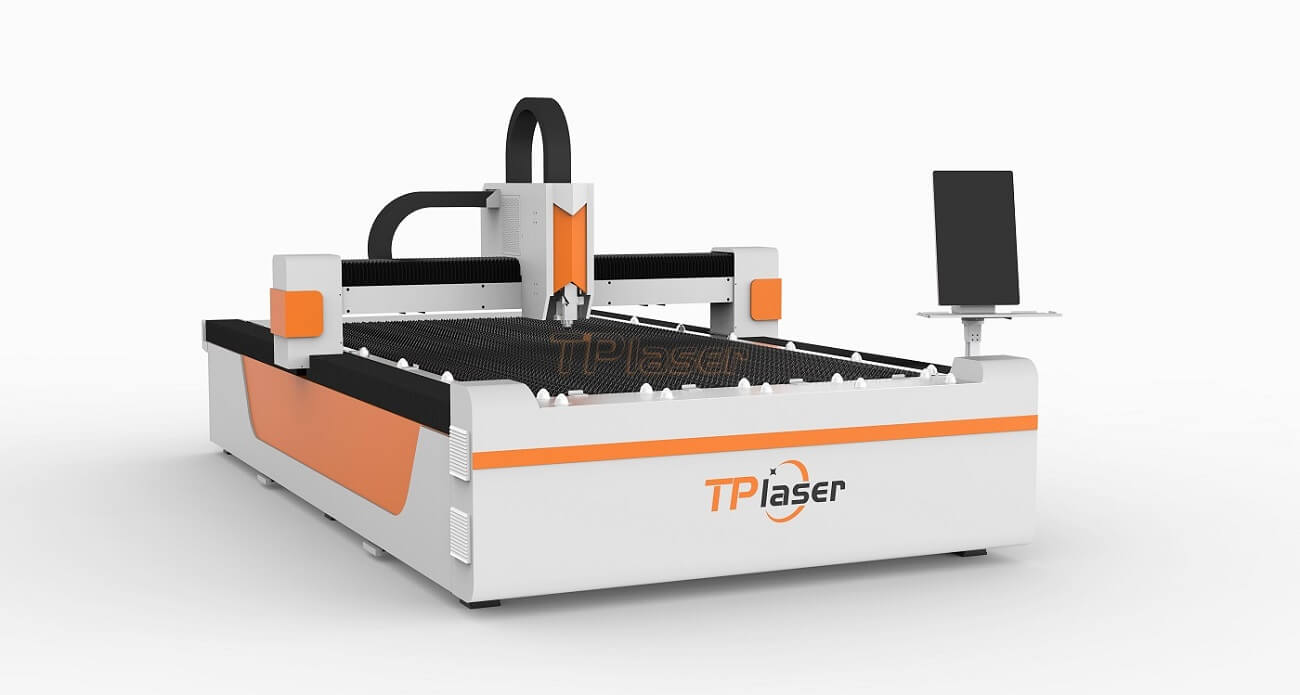

Buyer's ReviewsSheet metal laser cutter machine TPF4020 has a larger operating area, better operating space, stable overall performance, high efficiency and energy saving, and high cost performance.

Demonstration Video

Product Descriptions

Sheet metal laser cutter machine is a high-configuration, high-performance sheet metal laser cutting machine tailored by TPLASER for the low and medium power laser cutting market. The laser cutting machine adopts imported servo drive, Cypcut system and other configurations, with larger format and larger operating space, which greatly meets the needs of customers.

Features of Sheet Metal Laser Cutter Machine

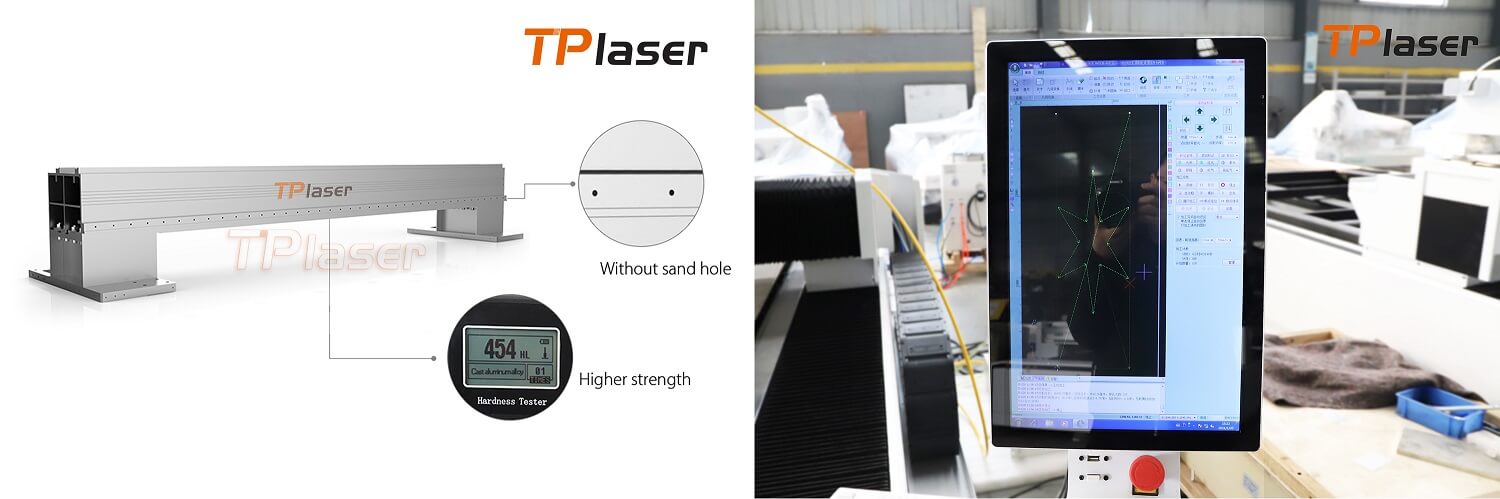

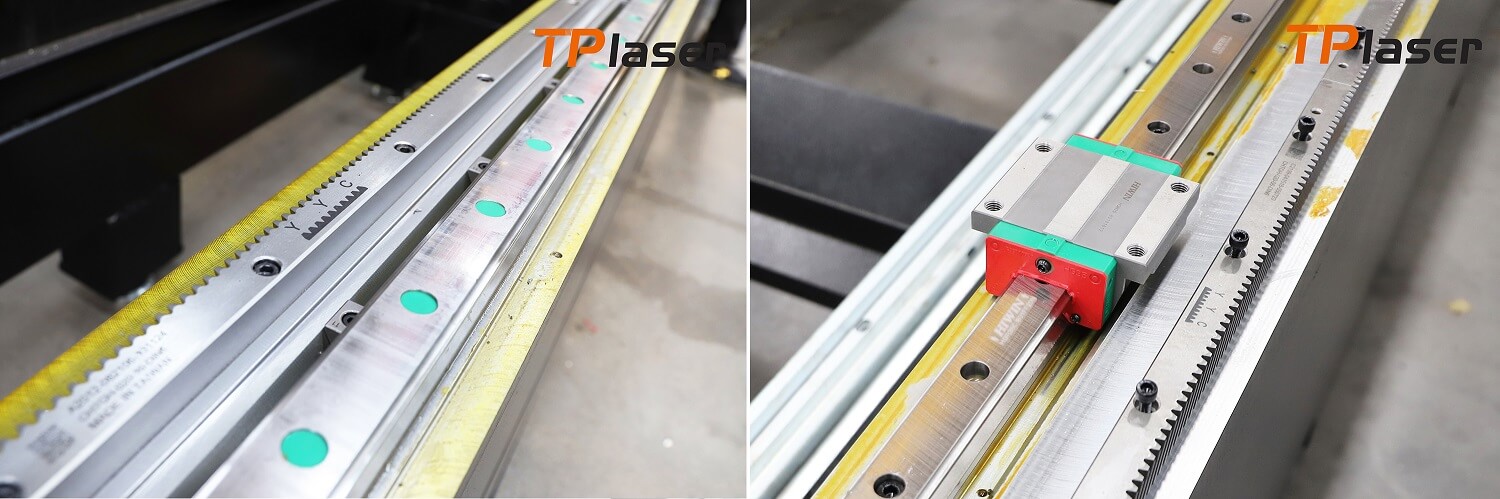

1.The overall bed has good rigidity; the guide rails are fully enclosed for protection to reduce dust pollution;

2.Imported servo motor is selected, with high precision, high acceleration and high speed;

3.Imported high-precision ball screw drive, imported high-precision linear guide;

4.Dedicated laser control system and professional CAM software, with powerful functions, stable operation, simple operation and easy learning;

5.Laser processing is non-contact flexible processing, which is not affected by the shape of the workpiece, and can process any graphics.

Advantages of Sheet Metal Laser Cutter Machine

1.Low cost, the laser power consumption is only 0.5-5 degrees per hour;

2.High performance, original packaged fiber laser, stable performance and long service life.

3.High speed, high efficiency

4.The laser is maintenance-free.

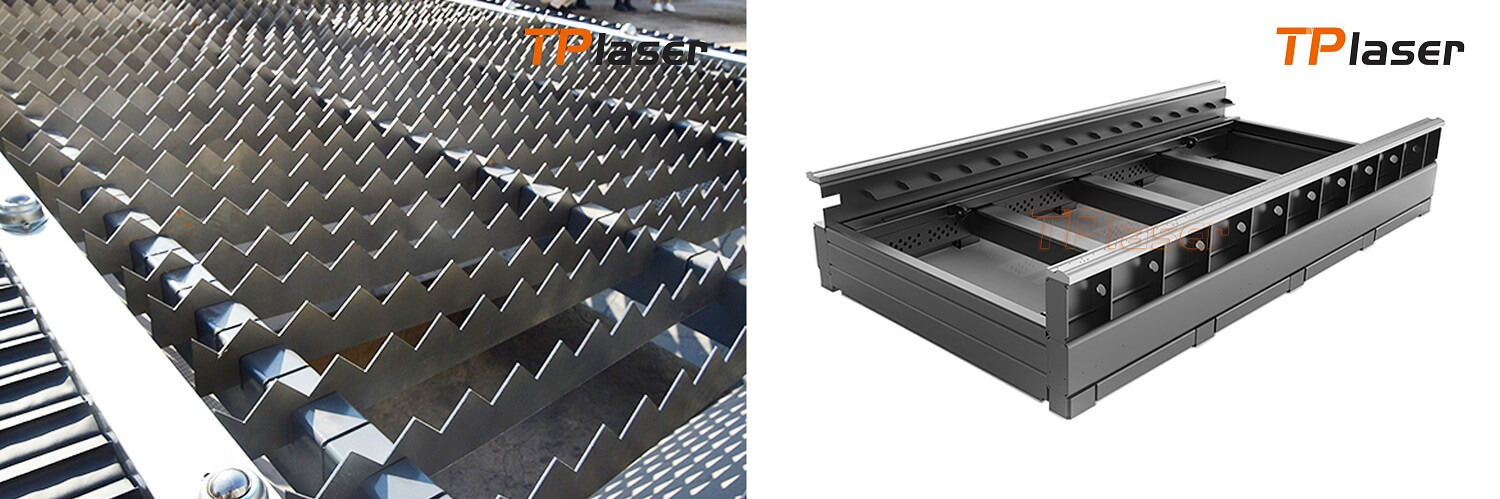

5.The quality of the cutting edge is good, the deformation is small, and the appearance is smooth and beautiful.

6.Adopt imported guide transmission mechanism and servo motor, with high cutting precision.

7.Various graphics or text can be designed at will and cut instantly, the operation is simple, flexible and convenient.

Specifications of Fiber Laser Cutting Machine

| Model | TPF4020 |

| Working ares | 1500*3000mm/2000*3000mm/2000*4000mm/2000*6000mm |

| Laser generate | Raycus/Max/IPG |

| Laser head | Raytools/Aut3tech/Precitec |

| Control system | Cypcut control system |

| Acceleration | 2.0G |

| Linkage Speed | 150m/min |

| Positional accuracy | ±0.02mm |

| Re-positional accuracy | ±0.01mm |

| Optional: | Automatic exchange platform |

| Enclosed protect cover | |

| Side rotary device (diameter: 120/170/220mm) |

Application of Sheet Metal Laser Cutter

Sheet metal laser cutter machine suitable for sheet metal processing, kitchen appliances, sheet metal chassis cabinets, lighting advertising, electrical equipment and various metal products processing industries.

Packing Detail of Sheet Metal Laser Cutter Machine

1. Strong water resit bottom in the plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing Inside steel frame protector.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container , then send to port ship to your country city.

Relevant Factors Affecting the Price of Sheet Metal Laser Cutter Machine

1.Machine configuration

The configuration of sheet metal laser cutter machine is different, and its price is also different. Most manufacturers will issue a configuration list in the process of customer consultation. There are different types of configurations in the configuration list, and the prices of different configurations are different (main configuration: laser, control system, laser head, motor and drive, etc.) .

2.Laser power

The laser power is the main cost of the sheet metal laser cutter machine. There will be differences in the equipment of the same configuration. Laser power and laser source brand will be different, and the price will also be different.

After Service of Sheet Metal Laser Cutter Machine

1.We will supplysheet metallaser cutter machine with training video and user’s manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

2.You can come to our laser machine factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

3.Our engineer will do a door-to-door instruction training service at your local site.