Product Introduction

Buyer's Reviews4*8ft Laser cutting machine is based on the classic model, and has been redesigned with a new design language. It has been upgraded on the basis of the original configuration, and the configuration is higher.

Demonstration Video

Product Descriptions

4*8ft Stainless steel laser cutting machine is a very cost-effective entry-level product for beginners. Its design structure is open and single-table. Features: simple structure, convenient installation, low maintenance cost; widely used in sheet metal cutting industry, Cabinet cutting industry, lighting accessories and other industries.

Features of Stainless Steel Laser Cutting Machine

1.A new generation of stainless steel laser cutting machine bed technology, the bed is not deformed;

2.The quality of the laser beam is more stable and the cutting effect is good;

3.High photoelectric conversion rate, which greatly saves work power consumption;

4.Intelligent operating system, import cutting graphics at will, and complete cutting with one key;

5.Lighter weight aviation aluminum beam, stronger strength, lighter weight and faster running speed;

6.Imported servo motor ensures that the machine starts and stops quickly and improves the running speed;

7.Low maintenance cost in the later period.

Specifications of Stainless Steel Laser Cutting Machine

| Model | TPF4020 |

| Working ares | 1500*3000mm/2000*3000mm/2000*4000mm/2000*6000mm |

| Laser generate | Raycus/Max/IPG |

| Laser head | Raytools/Aut3tech/Precitec |

| Control system | Cypcut control system |

| Acceleration | 2.0G |

| Linkage Speed | 150m/min |

| Positional accuracy | ±0.02mm |

| Re-positional accuracy | ±0.01mm |

| Optional: | Automatic exchange platform |

| Enclosed protect cover | |

| Side rotary device (diameter: 120/170/220mm) |

TPLaser Stainless Steel Laser Cutting Machine Advantages:

1.The Fifth Generation Aviation Aluminum Gantry

Aerospace aluminum is manufactured by aerospace standards. Aerospace aluminum has good toughness, light weight, corrosion resistance, oxidation resistance, low density, and greatly improves processing speed and processing accuracy.

2.No manual operation, simple operation auto focus (makes focus easier)

(1) Automatic adjustment: There is no need for manual manual focus adjustment. The software automatically adjusts the focusing mirror and controls the upper and lower heights, so as to realize automatic perforation and cutting of plates of different thicknesses.

(2) Large adjustment range: +10~-10, precision 0.01mm, suitable for different types of 0~20mm plates.

(3) Long life: The collimating lens and focusing lens are double water-cooled, which reduces the temperature of the cutting head and improves the life of the cutting head.

3.Independent control cabinet

(1) Dustproof: All electrical components and lasers are built into the independent control cabinet with dustproof design to improve the life of electrical components

(2) Automatic constant temperature: All electrical components and lasers are built in an independent control cabinet, and the outside of the control cabinet is equipped with an air-conditioning automatic constant temperature to prevent damage to components due to excessive temperature in summer.

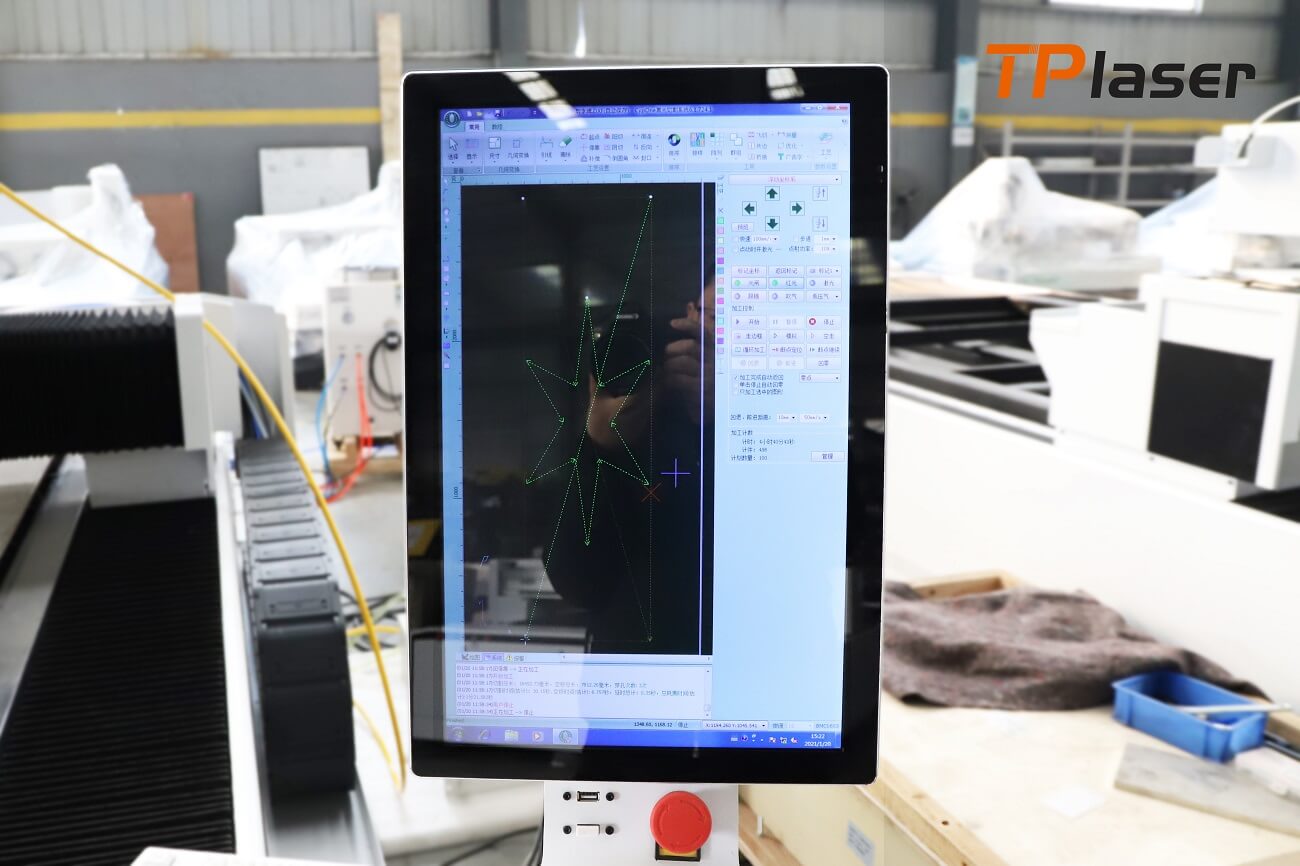

4.PAD design display

Apple pad design, vertical screen display, different from traditional horizontal screen display, fast response, high contrast, wide viewing angle, low power consumption, high resolution, higher brightness, lower reflectivity, toughened glass panel is durable.

Why Choose TPLaser Stainless Steel Laser Cutting Machine

1.Adopt advanced 6-axis robot welding equipment to weld stainless steel laser cutting machine bed in all directions, with high precision, superior to 90% of manufacturers in the market.

2.The world famous large gantry drilling machine is used to cut and drill the stainless steel laser cutting machine bed to ensure the accuracy of the machine operation

Packing Detail of Stainless Steel Laser Cutting Machine

1.Strong water resit bottom in the plywood.

2.Laser source (separated plywood case) and spare parts on the laser bed

3.Corner protect by foam and fixed by protective film.

4.All covered by strong and hard protective film.

5.Vacuum packing Inside steel frame protector.

6.Inside steel frame protector.

7.Plywood packing and steel strip outside fixed the box.

8.Finishing packing by normal container , then send to port ship to your country city.

Our Company

TPLaser adheres to the motto of “customer first, service first”. we believe in the spirit of enterprise“cooperation, win-win, appreciate and share “, and continue to attract top talents and precision laser technology to join us, TPLaser is a leading CNC equipment manufacturer in China and has launched 10 series products with an annual production capacity of 1,120 sets. With advanced CNC technology, perfect quality management system and convenient after-sales service in the network of mainland China and global markets.

If you are interested in any of our products or would like to discuss a custom order,please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.