Product Introduction

Buyer's ReviewsFlatbed fiber laser cutting system can mainly do plane cutting, and the edges are neat and smooth, which is suitable for high-precision cutting processing such as metal plates.

Demonstration Video

Product Descriptions

Flatbed fiber laser cutting system can cut a variety of metal sheets, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, various alloy sheets, rare metals and other materials; widely used in: kitchen appliances, sheet metal chassis Machine frame, machine frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment, various metal products, sheet metal cutting and other industries;

Features of Flatbed Fiber Laser Cutting System

1.Flatbed fiber laser cutting system adopts a heavy-duty gantry bilateral drive structure with good dynamic performance. The overall layout is compact, reasonable and occupies a small area.

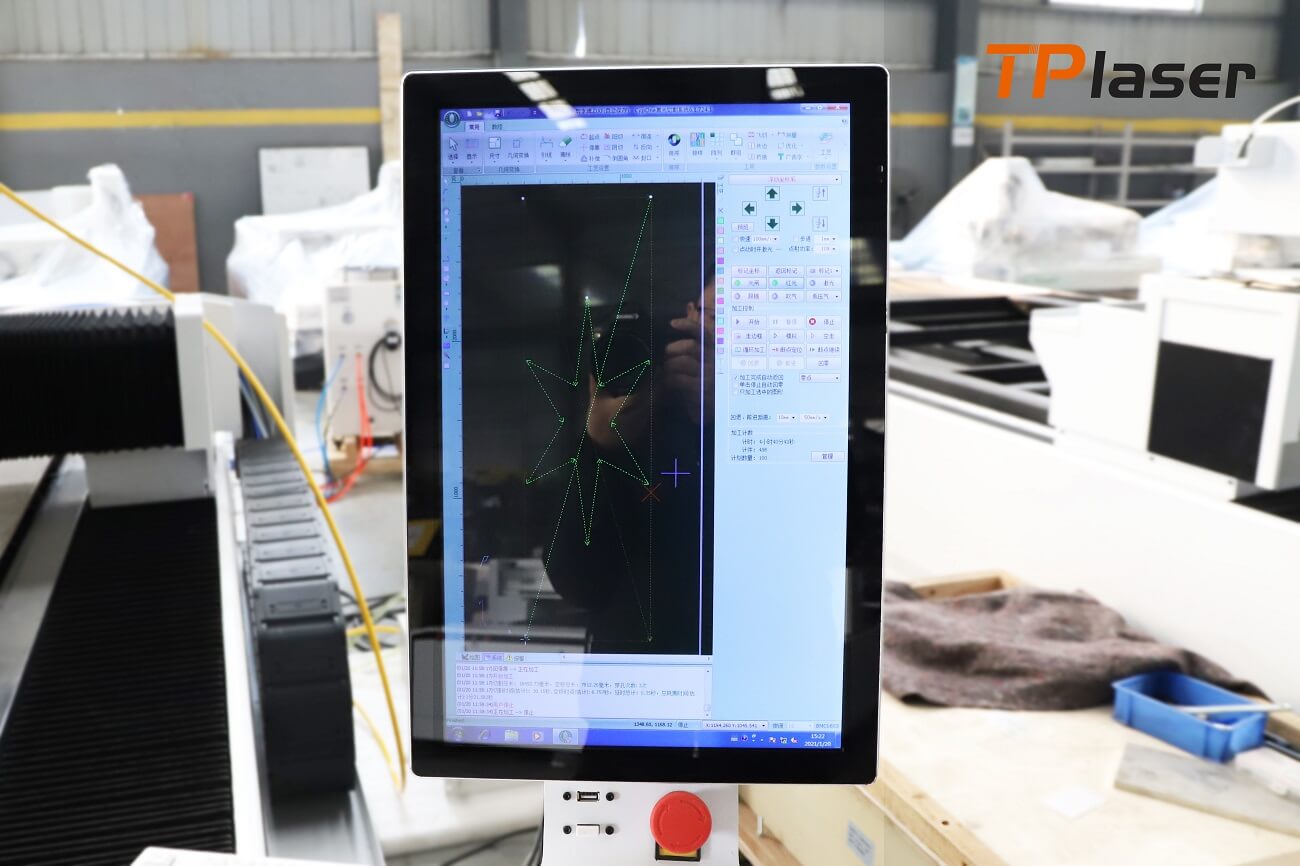

2.Flatbed fiber laser cutting system is equipped with a special laser numerical control system, which ensures the processing accuracy under high-speed operation conditions, high production efficiency and high processing accuracy.

3.Standard Raycus fiber laser (optional German IPG laser), low operation and maintenance cost, realize long-term return on investment and rapid income.

4.The key components of the cutting head use Swiss Raytools cutting head, non-contact capacitive sensing, strong safety protection measures, stable and reliable performance, and easy to use.

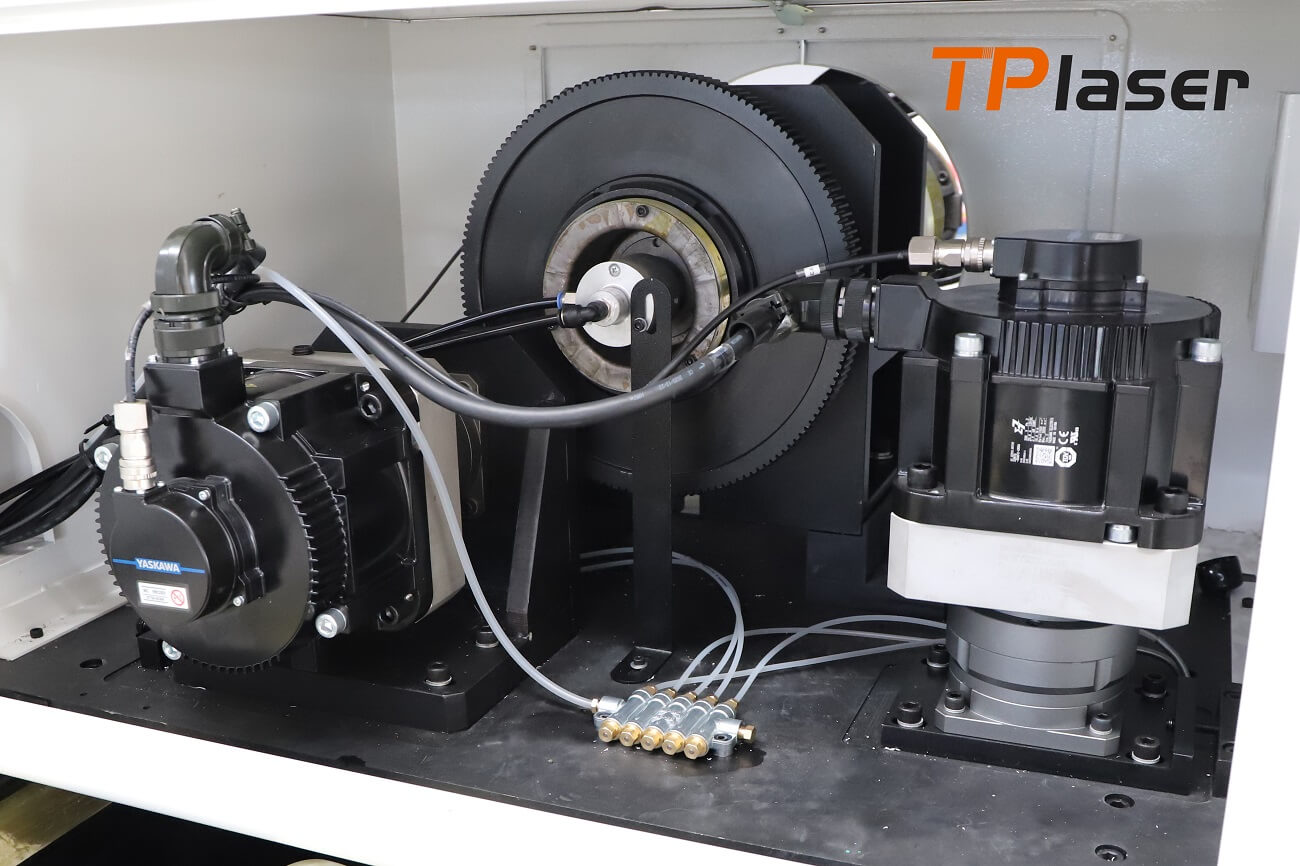

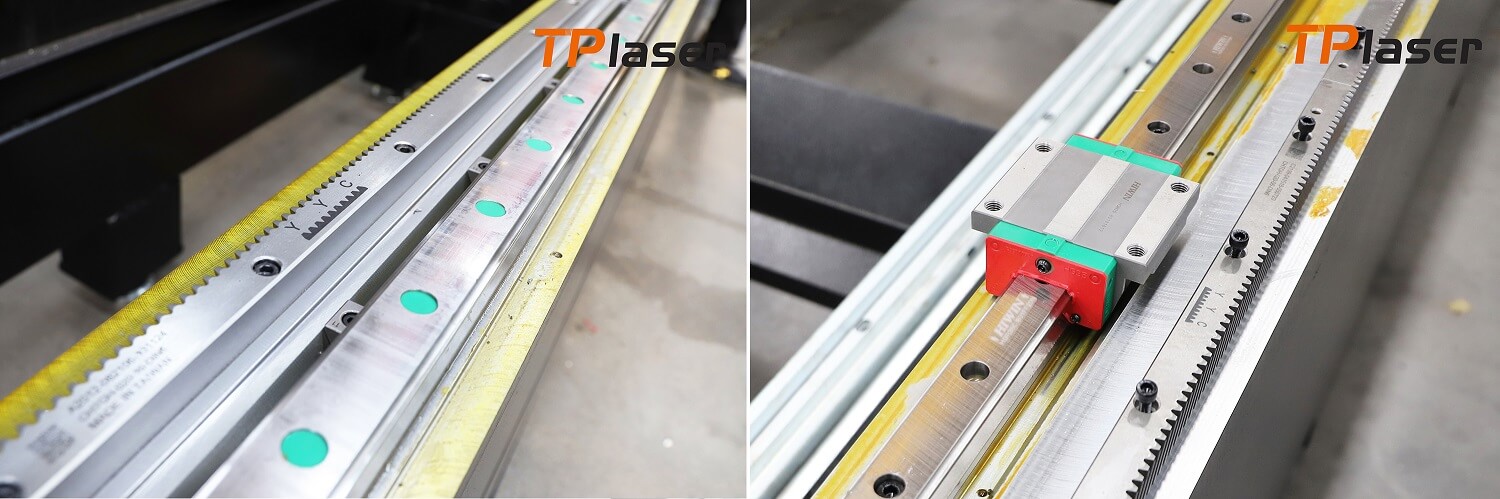

5.The X and Y axes adopt imported gear racks, guide rails, and are equipped with a centralized lubrication device to ensure long-term stable accuracy and reliable operation.

6.Design and manufacture a reinforced welding bed, which is tempered after welding and aging, and vibrates to eliminate stress to ensure the accuracy and stability of the bed for long-term operation.

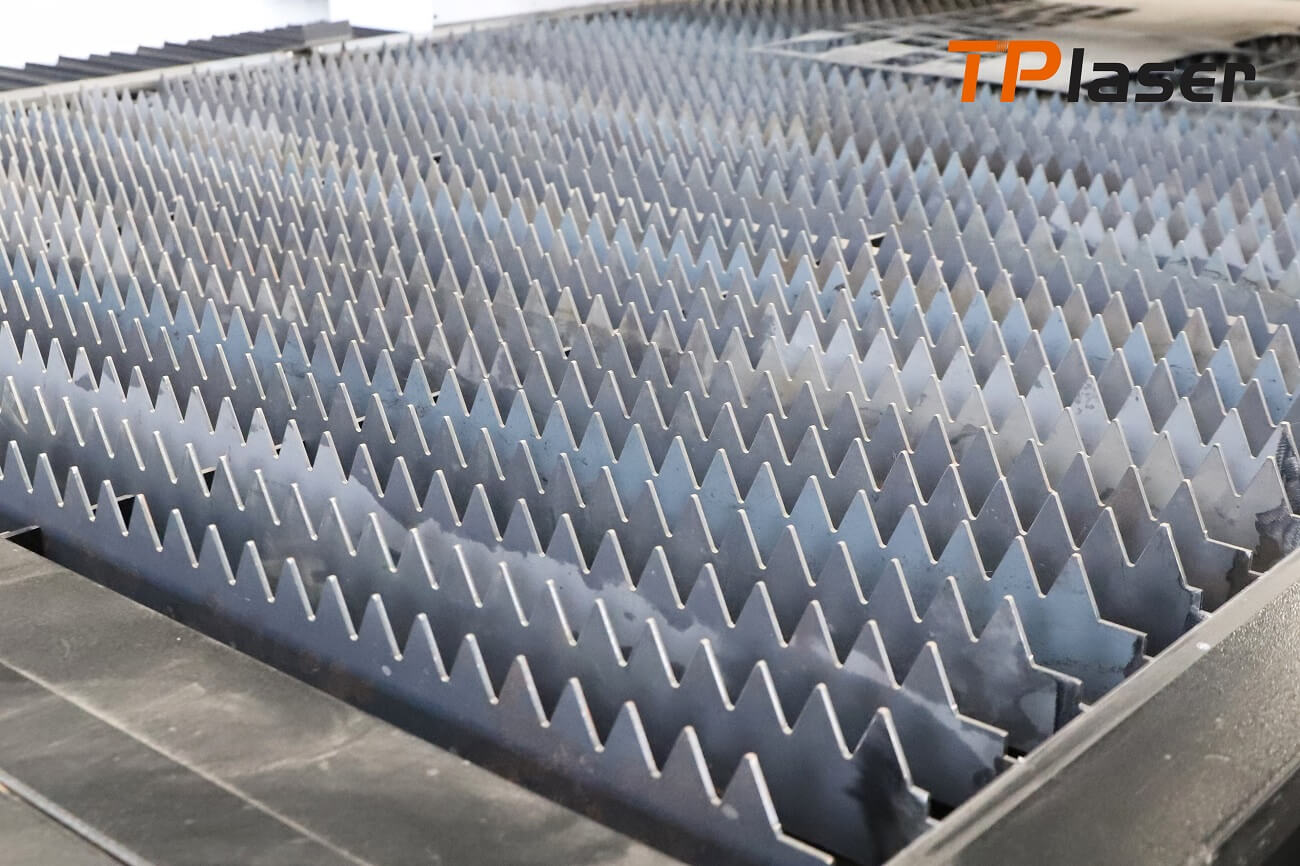

7.There is a trolley collection device under the machine tool, and the cut small materials and metal powder will be collected in the trolley for easy collection and processing.

8.Three kinds of auxiliary gas (high pressure air, nitrogen, oxygen) automatic conversion system are equipped as standard to meet the processing needs of customers for various materials, with simple operation and lower cost.

9.Standard high-end programming nesting software (including material management, processing technology optimization and other functions) has functions in drilling, sharp corner processing, etc. With a complete laser cutting process database, the operator only needs to call the corresponding cutting parameters according to the material and thickness, making the operation more intelligent and simplified.

10.Optimized optical lenses, specially designed nozzles and sensing technology make cutting smoother and more stable.

11.Flatbed fiber laser cutting system optional 4000mm*1500mm, 4000mm*2000mm and other specification workbenches.

Specifications of Flatbed Fiber Laser Cutting System

| Model | TPF6020 |

| Working ares | 1500*3000mm/2000*3000mm/2000*4000mm/2000*6000mm |

| Laser generate | Raycus/Max/IPG |

| Laser head | Raytools/Aut3tech/Precitec |

| Control system | Cypcut control system |

| Acceleration | 2.0G |

| Linkage Speed | 150m/min |

| Positional accuracy | ±0.02mm |

| Re-positional accuracy | ±0.01mm |

| Optional: | Automatic exchange platform |

| Enclosed protect cover | |

| Side rotary device (diameter: 120/170/220mm) |

Parts of Flatbed Fiber Laser Cutting System

Control system

Laser head

Laser generate

Why Choose TPLaser Flatbed Fiber Laser Cutting System

1.Adopt advanced 6-axis robot welding equipment to weld flatbed fiber laser cutting system bed in all directions, with high precision, superior to 90% of manufacturers in the market.

2.The world famous large gantry drilling machine is used to cut and drill the flatbed fiber laser cutting system bed to ensure the accuracy of the machine operation

Our Company

TPLaser adheres to the motto of “customer first, service first”. we believe in the spirit of enterprise“cooperation, win-win, appreciate and share “, and continue to attract top talents and precision laser technology to join us, TPLaser is a leading CNC equipment manufacturer in China and has launched 10 series products with an annual production capacity of 1,120 sets. With advanced CNC technology, perfect quality management system and convenient after-sales service in the network of mainland China and global markets.

If you are interested in any of our products or would like to discuss a custom order,please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.