Product Introduction

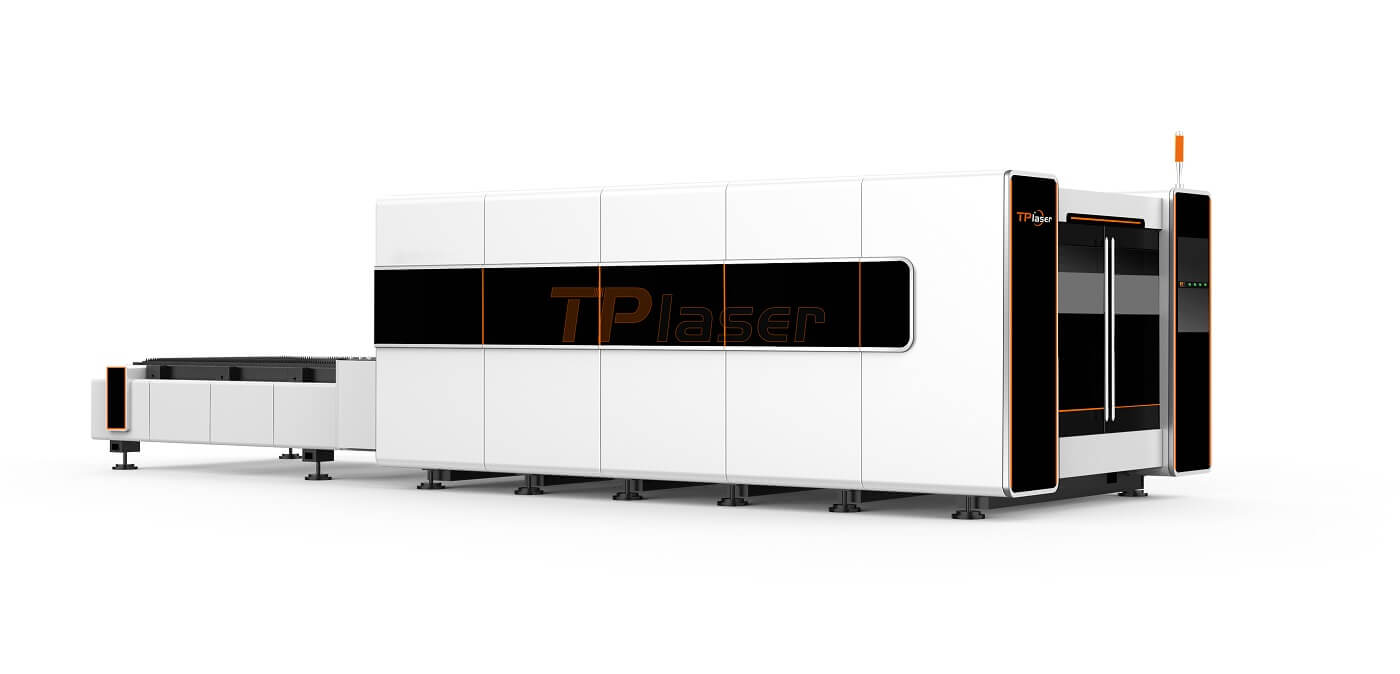

Buyer's ReviewsFiber laser cutter series products are specially used for metal material processing. With the fully enclosed safety design and interactive interchangeable workbench, the labor intensity is greatly reduced, the loading and unloading operation time is shortened, and the cutting effect and production efficiency are effectively improved.

Demonstration Video

Product Descriptions

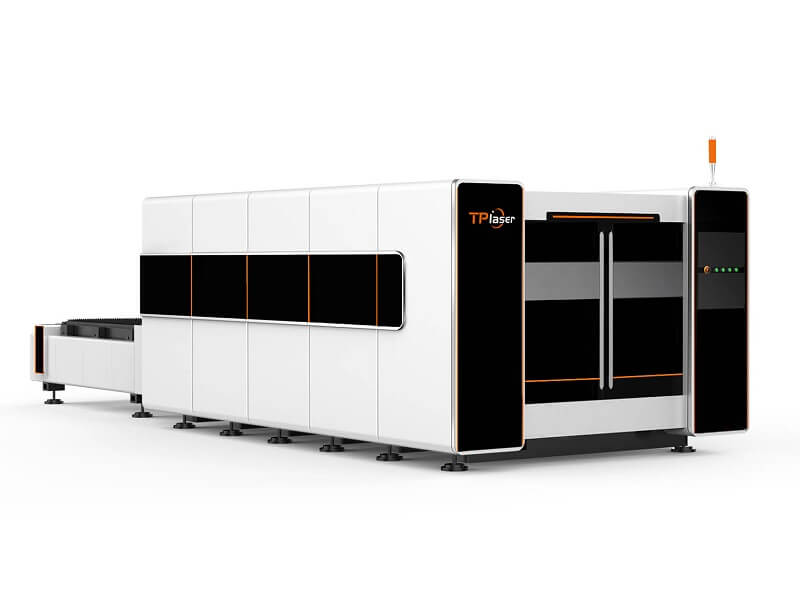

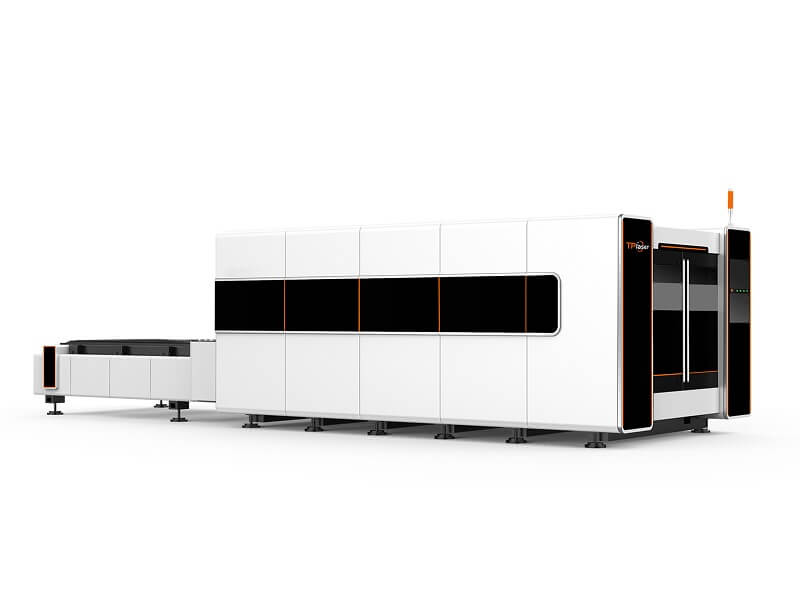

Fiber laser cutter is a high-power metal laser cutting machine. The blessing of the original imported laser has greatly improved the performance of this machine, and has better performance in sheet metal processing and metal cutting. Moreover, the laser cutting machine is equipped with a large surrounding protective cover on the periphery, which can effectively protect the safety of operators. The appearance is redesigned with a new design language, and it is equipped with an independent control cabinet to prevent dust and noise and improve the service life of the machine.

Advantages of Fiber Laser Cutter

1.Full protection humanized design

◆Fully enclosed laser protective glass design to prevent laser damage to personnel.

◆External dust removal and environmental protection equipment can be connected to achieve zero emission of harmful substances.

◆Professional laser cutting numerical control system, automatic edge finding and discharging, improve the utilization rate and production efficiency of plates;

2.fast exchange

◆High-speed parallel exchange table design, double worktables are exchanged at the same time, and the transmission mode is stable and reliable.

◆Fast, shorten the exchange time, save the auxiliary time of loading and unloading.

◆The frequency converter controls the exchange motor, and the machine tool can quickly complete the exchange.

3.surveillance system

◆The rear camera of the outer cover is convenient for the operator to monitor the dynamics of the side and rear in real time.

◆The protective cover has a built-in camera, which can monitor the equipment without stopping during operation, which reduces the incidence of accidents and facilitates the operator to observe the cutting process in real time.

Parameter of Fiber Laser Cutter:

| Model | TP2060EC |

| Laser Power | IPG/Raycus/Max/JPT 10,000W~30,000w |

| Enclosed Cover | Full Enclosed Protective Cover |

| Working Area | 2000*6000mm |

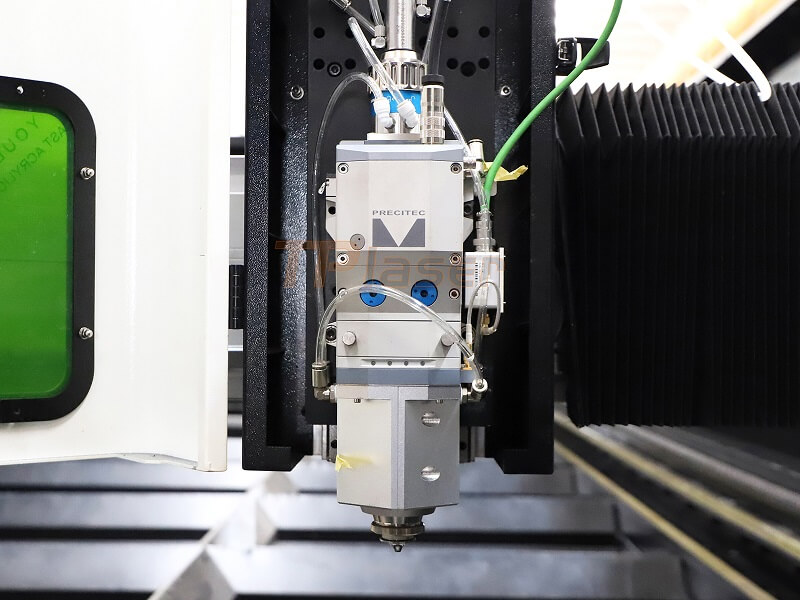

| Laser Head | German Precitec Auto Forcus Laser Head |

| Control System | Fuscut / Cypcut Control System |

| Moving Speed | 200m/min |

| Cutting Speed | 60m/min |

| Max.Acceleration | 2.8G |

| Positioning Accuracy / Repeat positioning Accuracy | ±0.02mm / ±0.01mm |

| Cooling System | Water Chiller Cooling |

| Power Supply | 3Phase 220V/380V 50-60HZ |

| Machine Weight | 6000KG |

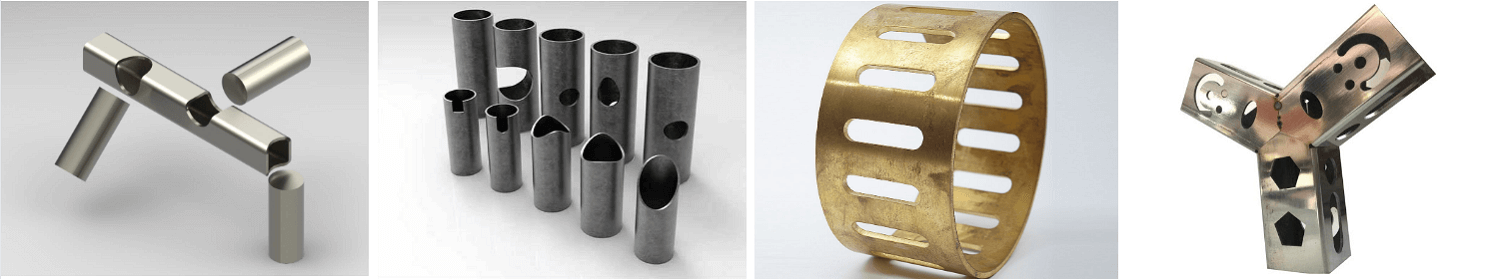

Parts Detail of Fiber Laser Cutter

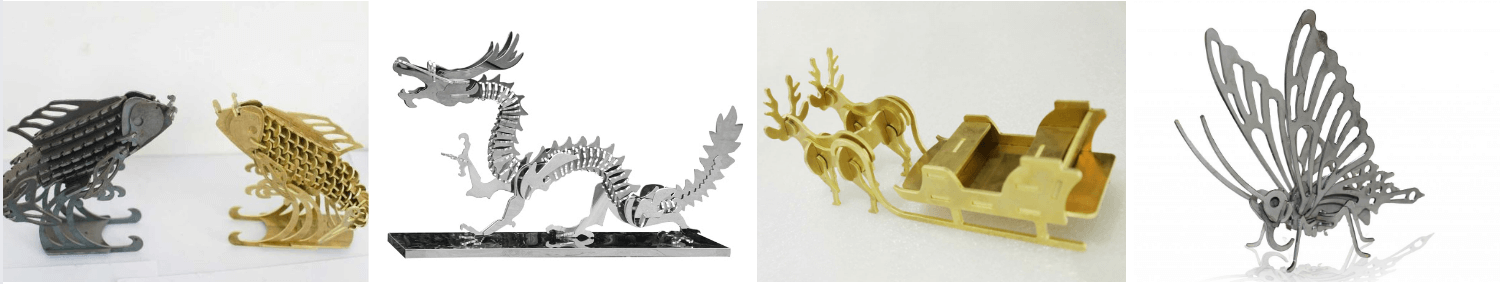

Applications of Fiber Laser Cutter

Application industry:

Suitable for sheet metal processing, kitchen appliances, sheet metal chassis cabinets, lighting advertising, electrical equipment and various metal products processing industries.

Applicable materials:

Professionally used in cutting carbon steel plate, stainless steel plate, galvanized plate, electrolytic plate, aluminum alloy, brass and copper and other metal materials.

How to Buy A Fiber Laser Cutter?

1.Inquiry: Our sales staff will provide suitable fiber laser cutter configuration according to the material and thickness you cut and your budget.

2.Communication and discussion: Both parties make configuration changes according to the customer’s requirements (provided that fiber laser machine quality and cutting effect are guaranteed), and solve customer’s machine parameters and configuration questions.

3.Make a quotation: We will make a quotation with the detailed configuration of the machine according to the results of the communication and discussion, so that the customer can understand fiber laser cuttermore clearly.

4.Cooperation between the two parties: If everything has beed confirmed, we will make a proforma invoice(PI) and sign a contract with the customer.

5.Start production: The customer arranges to pay a deposit after receiving the proforma invoice and contract. When we receive the deposit, we will immediately arrange the production machine and update the production process at any time.

6.Shipment: When fiber laser cutter machineis finished, we will send the customer a photo of the machine and test video (the whole machine will be tested before shipment to ensure that it can work well). After receiving the final payment from the customer, we will arrange for the machine to be sent to your country.

7.Customs clearance: We will provide all necessary customs clearance documents according to the customer’s national customs requirements to ensure the smooth customs clearance of the customer.

8.After-sales service: When the customer receives the machine, our engineers will provide you with installation and operation services (of course, the machine also comes with installation and operation manuals and videos), and we will contact you via Email, Skype, Whatsapp or other contact software Communication, we are online 24 hours, if you have any questions about the machine, you can contact us at any time.