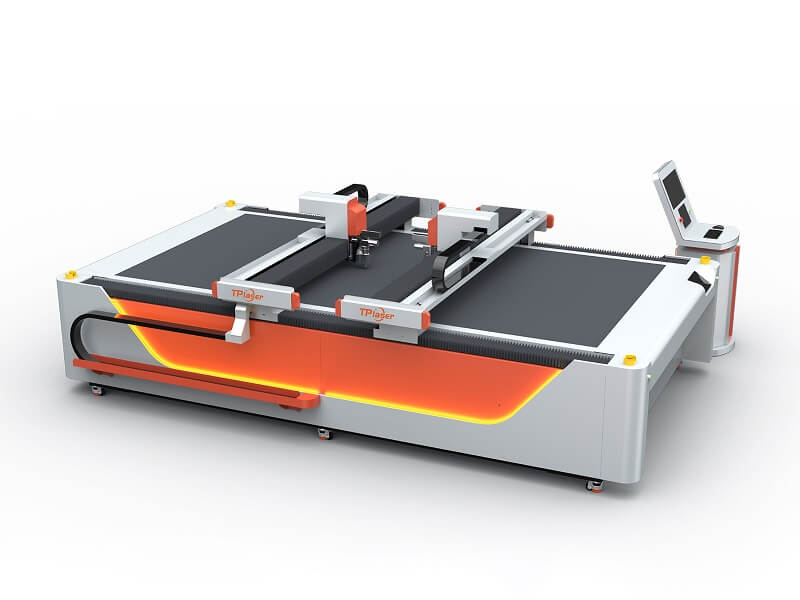

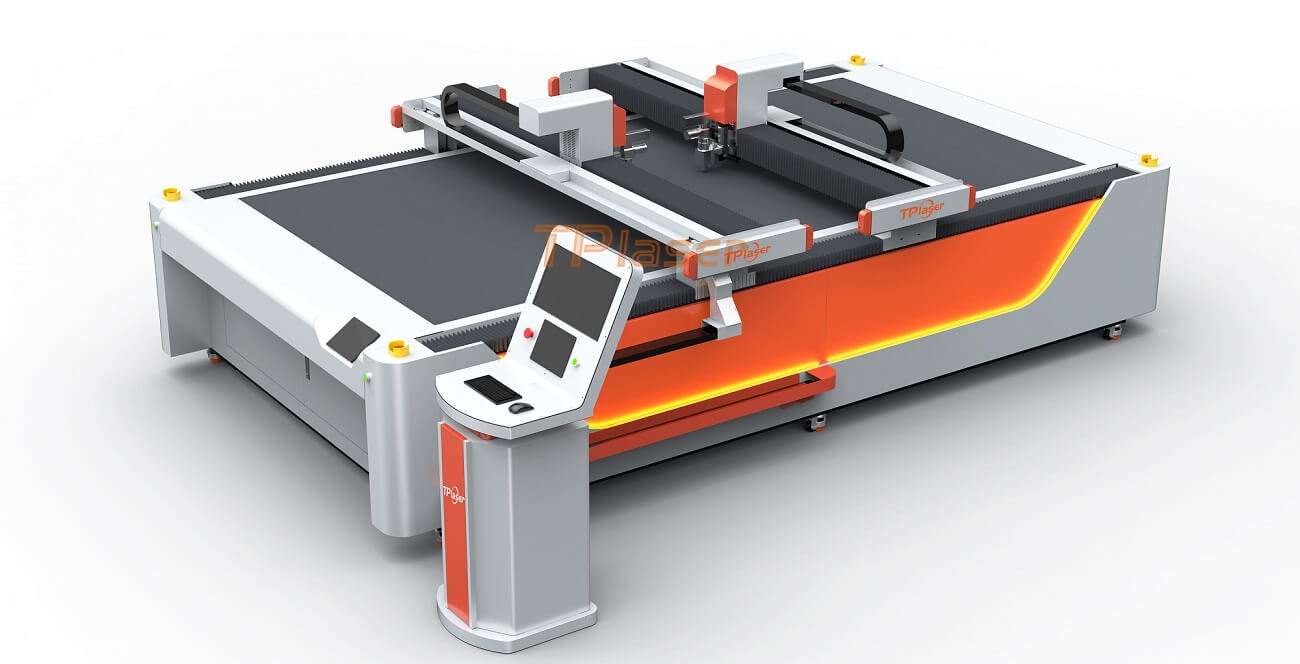

Product Introduction

Buyer's ReviewsCNC corrugated cardboard cutting machine can cut flexible non-metallic materials, including: corrugated paper, car mats, car interiors, cartons, color boxes, soft PVC crystal pads, composite sealing ring materials, leather, shoe soles, cardboard, kt board, pearl cotton , sponge, composite material, plush stationery, etc.

Demonstration Video

Product Descriptions

Corrugated cardboard cutting machine is a main product of our company. It adopts vibrating knife cutting technology and does not need to make knife molds, which saves the cost and time of knife mold manufacturing, management, storage, etc. in the process of production and development, and bids farewell to traditional manual work. The die cutting process completely breaks through the bottleneck of enterprises relying on skilled workers, and takes the lead in entering the era of digital dieless processing.

Features of Corrugated Cardboard Cutting Machine

1.The CNC corrugated cardboard cutting machine has stable performance and high precision, which can meet the needs of diversified design and processing.

2.Professional design software, box-type library, box-type screen 3D proofing, box-type data and many other functions, with standard, fast, efficient, high-precision, intelligent and other characteristics, to achieve the purpose of fast, time-saving and cost reduction.

3.The CNC corrugated cardboard cutting machine can be widely used for design proofing and small batch production of packaging carton enterprises, and can cut corrugated cardboard, cardboard, honeycomb cardboard, foam board, plastic board, etc.

4.It has the functions of low design cost, reduced design time, and improved design efficiency, which can show users all the concepts and innovative spirit of serving users.

5.The CNC corrugated cardboard cutting machine can improve your design technology and have more advanced design concepts, which can enhance the corporate image and increase the chances of business orders.

6.The CNC corrugated cardboard cutting machine has a variety of functions: vibrating knife cutting function, pressing folding line function, cutting half knife, positioning function, drawing function, etc. It is easy to operate, stable in performance and strong in durability.

Functions of CNC Corrugated Cardboard Cutting Machine

1.The cutting depth can be adjusted arbitrarily.

2.The parameter setting of the corrugated cardboard cutting machine is very simple. Different materials can be processed as long as the thickness and speed are set.

3.It is easy to expand the device upgrade function and load new modules.

4.Folding line pressing function: Folding lines can be pressed on corrugated paper, cardboard, rubber sheet and other materials.

5.Dotted line cutting function: used for folding and dotted line cutting after half-cutting of corrugated paper and cardboard.

6.The positioning function of the vibrating knife cutting machine: laser precise positionin.

Specifications of Corrugated Cardboard Cutting Machine

| Model | TPK1625/1825/2030 |

| Working size | Accept customization |

| Multifunctional cutting head | Replaceable vibrating knives, semi-penetrating knives, oblique knives, pressure rollers and other tools |

| Tool configuration | Various cutting tools, pressure wheel, pen, cross positioning laser |

| Security configuration | Highly sensitive infrared sensor (optional) |

| Moving speed | Up to 1200mm/s |

| Working speed | Up to 800mm/s (set according to different cutting materials) |

| Cutting material | EPS, foam, sponge, car floor seat cover, sofa cover, genuine leather, clothing fabric, corrugated paper, chevron board, kt board,etc. |

| Cutting thickness | Maximum 50mm (depending on different materials) |

| Material fixing method | High-power vacuum adsorption and intelligent partition |

| Repeatability | 0.01mm |

| Mechanical accuracy | 0.02mm |

| Transmission system | Steel wire timing belt, AC servo motor, linear guide |

| Control System | Dual 32-bit RISC core cpu + large-scale programmable logic array FPGA |

| Display method | Chinese and English LCD touch screen |

Details of Corrugated Cardboard Cutting Machine

Samples of Corrugated Cardboard Cutting Machine

Packing of Corrugated Cardboard Cutting Machine

1). Outside package: with standard marine export plywood box.

2). Inner package: use stretchy film and plastic film.

3). English software, User manual and detail installation and training videos in USB when delivery.

4). Some extra spare parts in the tools box (Such as electrical components, limit switches etc.)

After Service of Corrugated Cardboard Cutting Machine

1.We will supply corrugated cardboard cutting machinewith training video and user’s manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

2.You can come to our factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

3.Our engineer will do a door-to-door instruction training service at your local site.