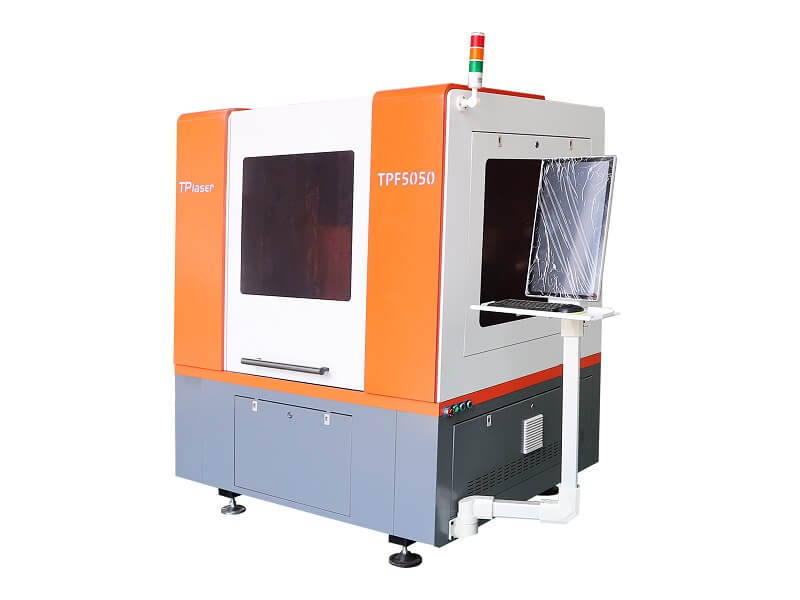

Product Introduction

Buyer's ReviewsSmall metal laser cutting machine refers to a small area laser cutting machine specially used in small processing factories. It is a popular equipment among laser cutting machines. The so-called small metal laser cutting machine is the energy released when the laser beam is irradiated on the surface of the workpiece. To melt and evaporate the workpiece to achieve the purpose of cutting and engraving.

Demonstration Video

Product Descriptions

Advantages of Small Metal Laser Cutting Machine

1.The small metal laser cutting machine can guarantee the cutting of smaller format, and is more suitable for some small metal materials, such as advertisements, kitchen utensils, etc. Comparatively speaking, the power is also lower than that of ordinary fiber laser cutting machines.

2.The cost of small metal laser cutting machines is relatively low, which is very suitable for small enterprises or enterprises with small processing volume. Small fiber laser cutting machines occupy a relatively small area, so they are more convenient for placement and handling.

3.The precision of the small metal laser cutting machine is relatively high, and the focused spot is relatively fine, the cutting accuracy can reach 0.1mm, and the cut surface is also very smooth. In addition, its cutting speed is also very fast, more than 100 times that of wire cutting.

4.The cost of small metal laser cutting machine is relatively low.

Applicable industries:

Mainly used in the glasses industry, craft gifts, hardware accessories, electronics, electrical appliances and other precision metal products industries.

Specifications of Small Metal Laser Cutting Machine

| Model | TPF6060 |

| Working area | 600*600mm |

| Laser type | Fiber laser |

| Laser power | 1000w |

| Laser Source | Raycus brand |

| Control system | Cypcut control system |

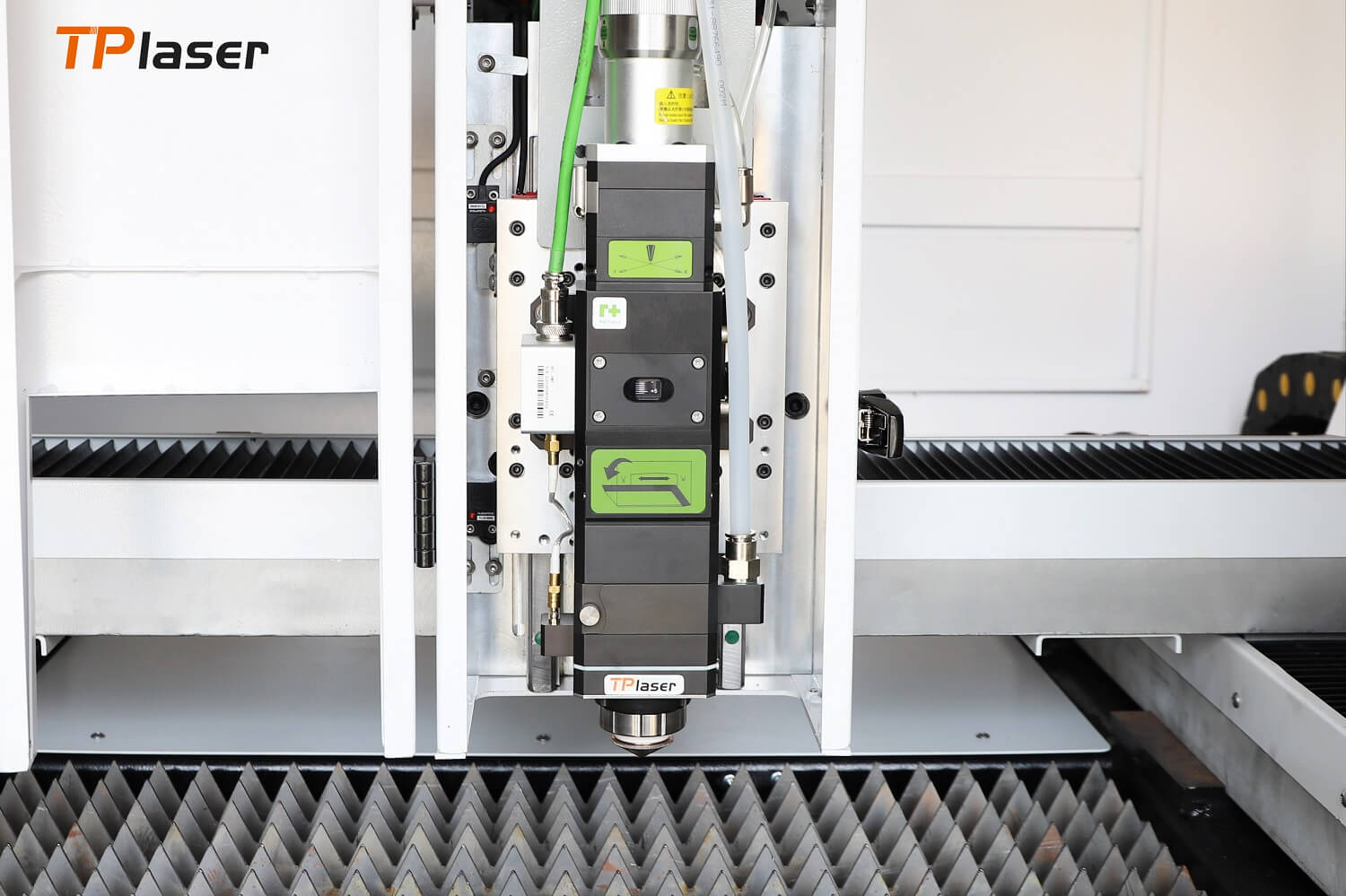

| Laser head | Raytools laser head |

| Motor and driver | Japan Yaskawa motor and driver |

| Acceleration | 1.5g |

| Linkage Speed | 140m/min |

| Positional accuracy | ±0.03mm |

| Re-positional accuracy | ±0.02mm |

| Weight: | 1500kg |

Features of Small Metal Laser Cutting Machine

1.Fast cutting speed. The small metal laser cutting machine has a fast cutting speed, which can reach 2.5m/min, which is more than 100 times that of wire cutting.

2.Low maintenance cost. Easy maintenance and low cost.

3.Diversified product forms. The small metal laser cutting machine is controlled by computer and can cut any complex graphics, ensuring production flexibility and product diversification. Meet the order needs of different customers.

Quality Assurance

How to use small laser cutting machine

1.When using a metal laser cutting machine, it is necessary to clean its guide rails frequently, wipe the rack of the equipment frequently, and apply lubricating oil frequently on the guide rails to ensure that there are no sundries.

2.the motor ring should also be cleaned regularly to clean the lubricating oil, which is conducive to ensuring the operation of the fiber laser cutting machine, and can also be accurately cut to ensure the quality of the cutting products.

3.Every week, the equipment management personnel must use the vacuum cleaner to suck away the dust and sundries in the machine, and ensure that all electrical cabinets are protected from dust. Finally, if you want to ensure the service life of the fiber laser cutting machine, you need to check the straightness and verticality of its track every six months. Once it is found to be abnormal, it must be maintained and debugged in time.