Product Introduction

Buyer's ReviewsMini fiber laser cutting machine is an industry-specific laser equipment with the characteristics of high single-machine processing efficiency, completely dust-free, stress-free, burr-free, and smooth and neat cutting edges. It can be used in various metal sheet/auto parts/hardware processing .

Demonstration Video

Product Descriptions

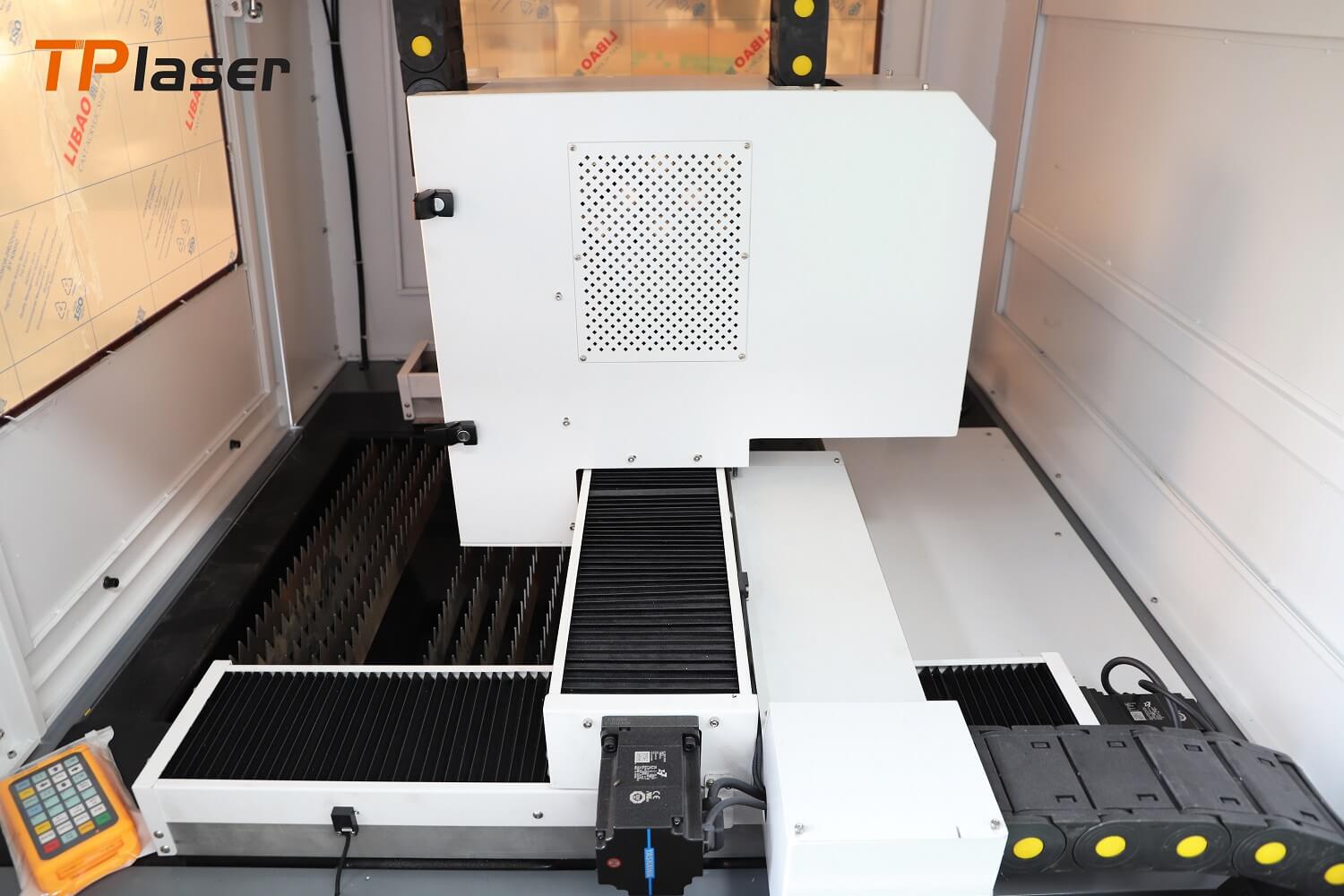

TPF6060 is TPLASER’s mini fiber laser cutting machine with leading technology, which is specially tailored for the needs of the medium and small power laser cutting market. TPF6060 series products are the first choice for the small-format metal material processing industry, and have fixed plate fixtures. This series of cutting machines has high cutting efficiency, beautiful slits, low operating costs, and powerful operating software.It is an advanced flexible processing equipment necessary for medium and small format processing.

Features of Mini Fiber Laser Cutting Machine

- The mini fiber laser cutting machine adopts a fully enclosed and enclosed anti-laser radiation design to reduce dust pollution and reduce the impact on operators; the overall appearance is high-grade, compact and reasonable, and convenient for placement and use.

- The cutting table adopts natural marble gantry structure, the overall bed has good cutting performance, high precision and stable operation.

- Imported high-speed and high-precision linear motor or double screw, double-motor transmission system and negative pressure adsorption system, accurate positioning, high acceleration, high processing stability, and effectively improve production efficiency.

- Standard high-performance special laser cutting head, laser, optical components and numerical control system ensure long-term running speed, accuracy, reliability and stability.

- The whole system has perfect optical path self-protection function and multi-channel closed-loop protection system; the whole machine has a powerful self-diagnosis function, which can quickly prompt the internal and external alarms of the machine tool.

- There is no need to add any lubricating fluid in the green processing process, and the dust extraction effect of the machine is good, which reduces the pollution to the product.

- The optical path of the whole machine is conducted by optical fibers, and the external optical path is maintenance-free, and the consumption of fragile quantities is very small.

- Laser non-contact processing, no tool cost, one-time molding, no need for repeated processing, saving cost and reducing scratches and wear on the surface of the material.

- The mini fiber laser cutting machine adopts professional laser cutting software, which has the functions of graphic layout and sharp corner smoothing, which can realize high-speed cutting and punching machine marking functions, and real-time feedback of the software interface, which can provide rich and open Laser Process Database.

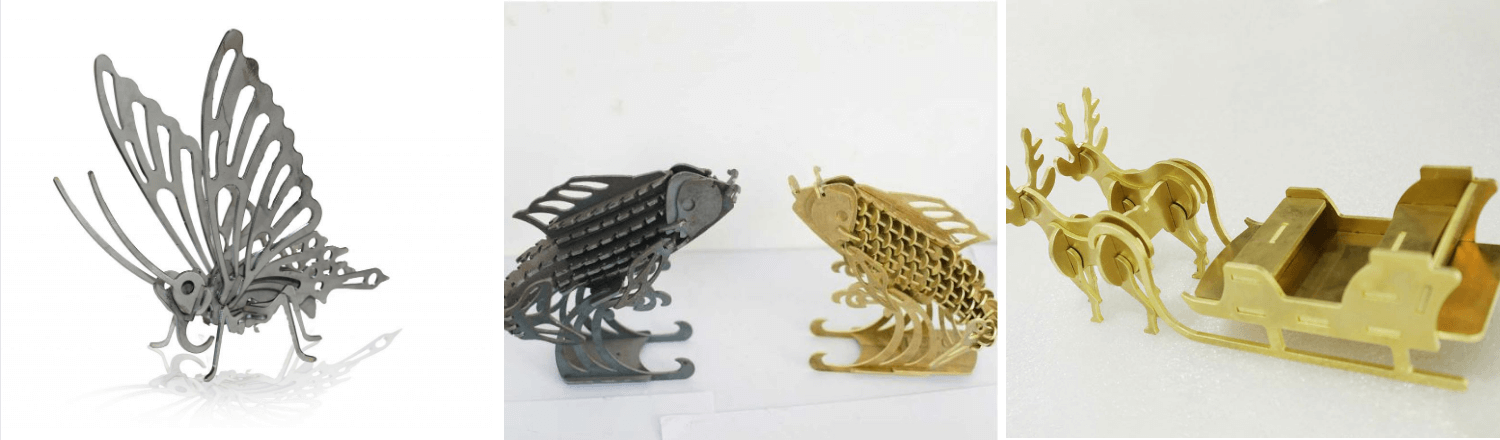

- The operation is flexible, simple and intuitive, with high efficiency. Various graphics or texts can be freely designed to achieve simultaneous output of various working methods such as instant cutting, micro-hole drilling, and engraving.

- Large-format worktable, high-precision visual positioning, chuck fixture, loading bin, protective cover and automatic feeding device can be customized according to actual needs.

Parts of Mini Fiber Laser Machine

Advantages of Mini Fiber Laser Cutting Machine

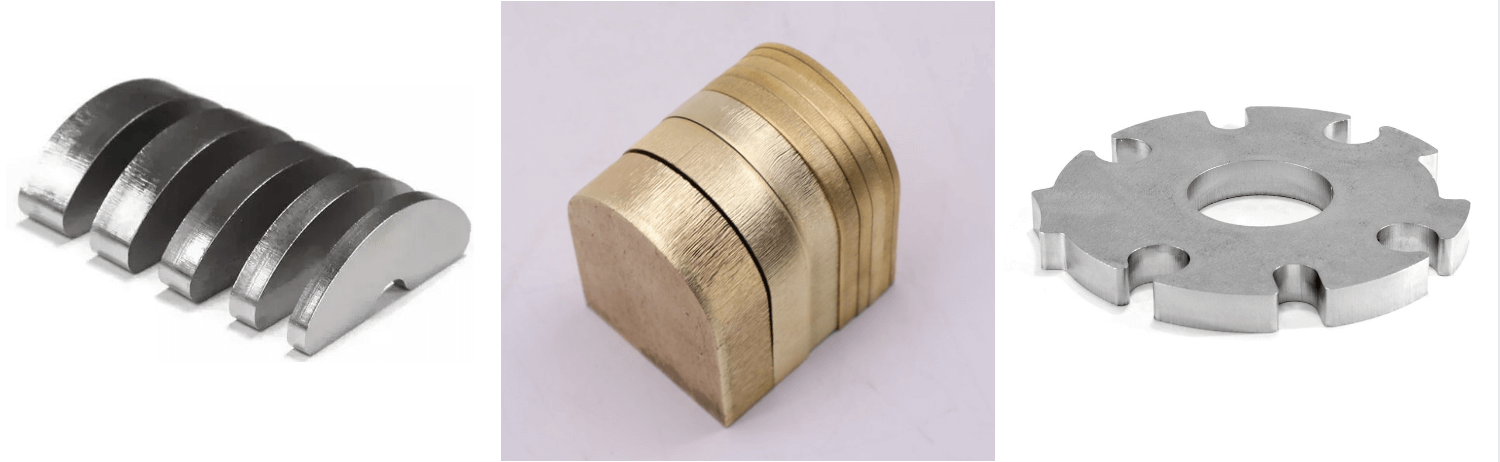

- The cutting effect of the mini fiber laser cutting machine is very good, the precision is high, it is not easy to make mistakes, and the quality of the processed products is good.

- The operation is simple, with a special control system. No matter how complex the graphics are, the machine can be completed automatically and accurately, which can reduce the work pressure of the factory and workers, and also greatly reduce the processing steps.

- The precision laser cutting machine is of good quality, not easy to break, low maintenance cost, power saving, durable and advanced than traditional laser equipment.

- Precise cutting, widely used in all walks of life, with a wide range, good reputation and high recognition.

Application of Mini Fiber Laser Cutting Machine

The mini fiber laser cutting machine can be applied to sapphire, ceramics, silicon, and various metal sheets to quickly achieve precise cutting, drilling, chamfering and surface treatment. It is widely used in precision mechanical hardware such as glasses, electronics, electrical appliances, superhard materials such as diamond, 3C such as magnesium aluminum alloy cutting and drilling, and microelectronics industries that require high cutting accuracy.

Specification of Mini Fiber Laser Cutting Machine

| Model | TPF6060 |

| Working area | 600*600mm |

| Laser type | Fiber laser |

| Laser power | 1000w/2000w/3000w/4000w |

| Laser Source | Raycus brand |

| Control system | Cypcut control system |

| Laser head | Raytools laser head |

| Motor and driver | Japan Yaskawa motor and driver |

| Acceleration | 1.5g |

| Linkage Speed | 140m/min |

| Positional accuracy | ±0.03mm |

| Re-positional accuracy | ±0.02mm |

| Weight: | 1500kg |

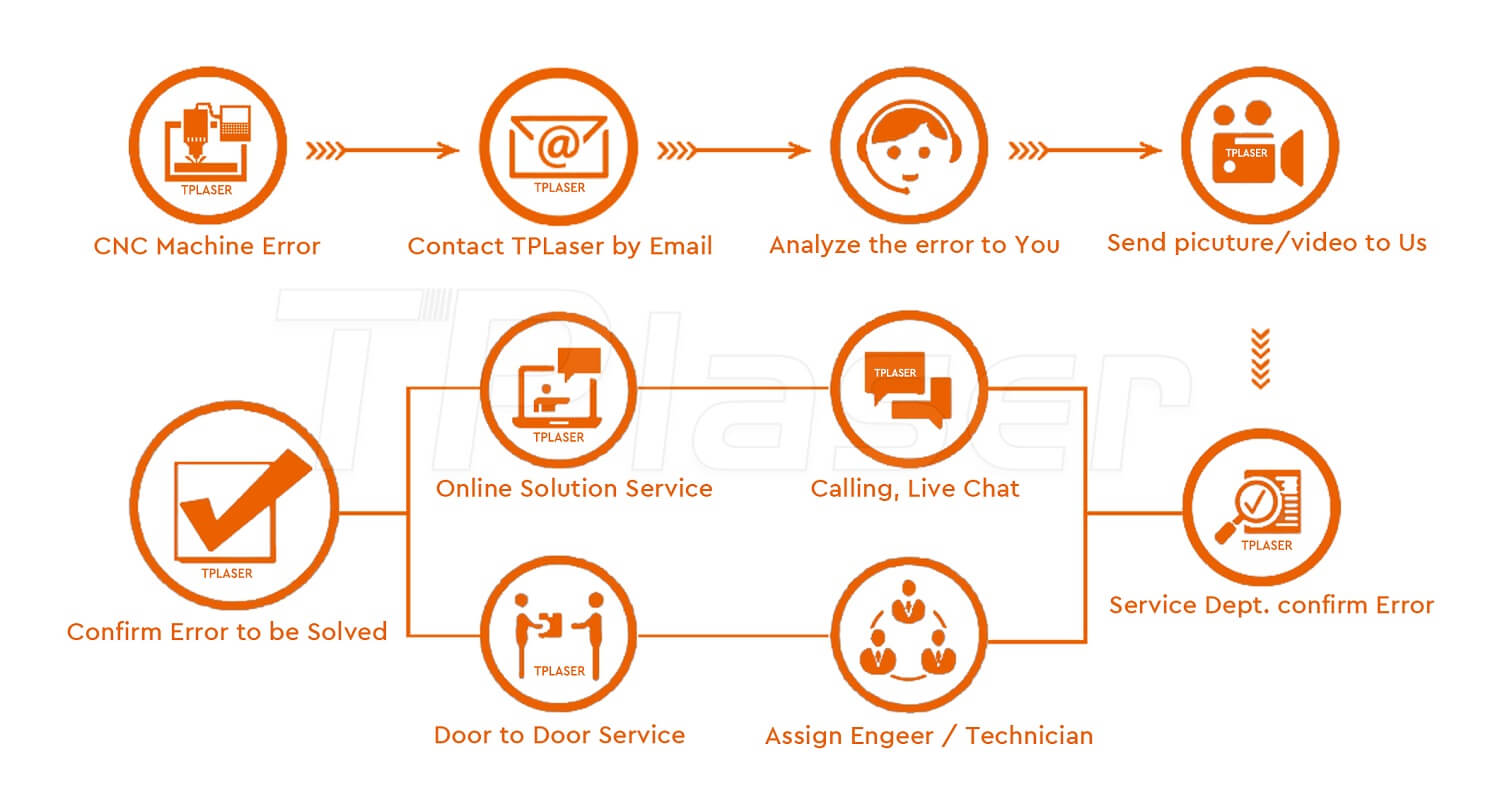

After Service of Mini Fiber Laser

After Service of Fiber Laser.

1. We will supply the laser machine with training video and user’s manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

2. You can come to our laser machine factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

1. 3 years for the whole metal laser welding machine, laser device 18 months, chiller 12 months, lens/mirror/nozzle without

warranty.

2. Long life-time maintenance, after-sale department will offer 24/7 English online support.

3. Except the damage artificially, we are responsible for offering the fittings free of charge during warranty.

4. After the warranty period expired, the buyer only need to pay the actual maintenance cost.

5. Certificate support: CE, SGS.

Our Company

Shandong TPLaser Technology Co.,Ltd, is a leading CNC equipment manufacturer in China and has launched 10 series products with an annual production capacity of 1,120 sets. With advanced CNC technology, perfect quality management system and convenient after-sales service in the network of mainland China and global markets.

If you are interested in any of our products or would like to discuss a custom order,please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.