Product Introduction

Buyer's ReviewsHandheld laser welding machine adopts an integrated design with a compact and beautiful structure. The handheld laser welder has the characteristics of good beam pattern, stable energy, fast welding speed, wide range of suitable welding, and long service life of consumables and consumable parts. TPLaser provides you with a professional portable handheld fiber laser welding machine.

Demonstration Video

Product Descriptions

Handheld laser welding machine is a new generation of laser welding equipment. It belongs to non-contact welding. The whole process of work does not need to be charged. The basic principle is to irradiate a laser beam with high-efficiency energy and compressive strength to the surface of the raw material immediately. The interaction between the laser and the raw material melts the inside of the raw material, and then cools and crystallizes to produce welding.

The fiber laser welder makes up for the vacancy of hand-held welding in the field of laser machinery and equipment, and overturns the working mode of the traditional laser welding machine. It replaces the previously fixed laser light path with a hand-held type, which is convenient and convenient, and the welding distance is long. It is very possible for laser welding to actually operate outdoors.

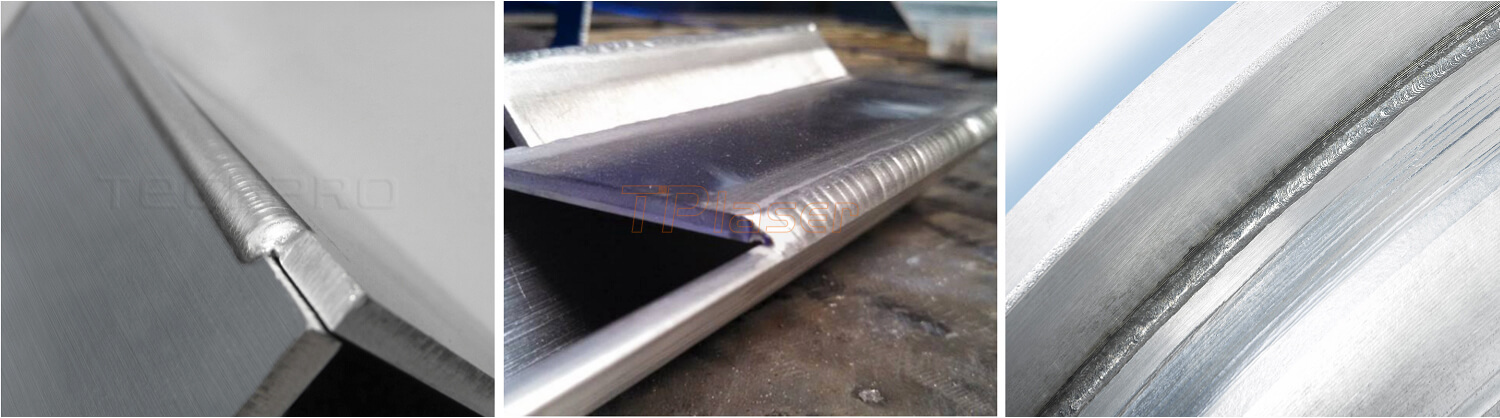

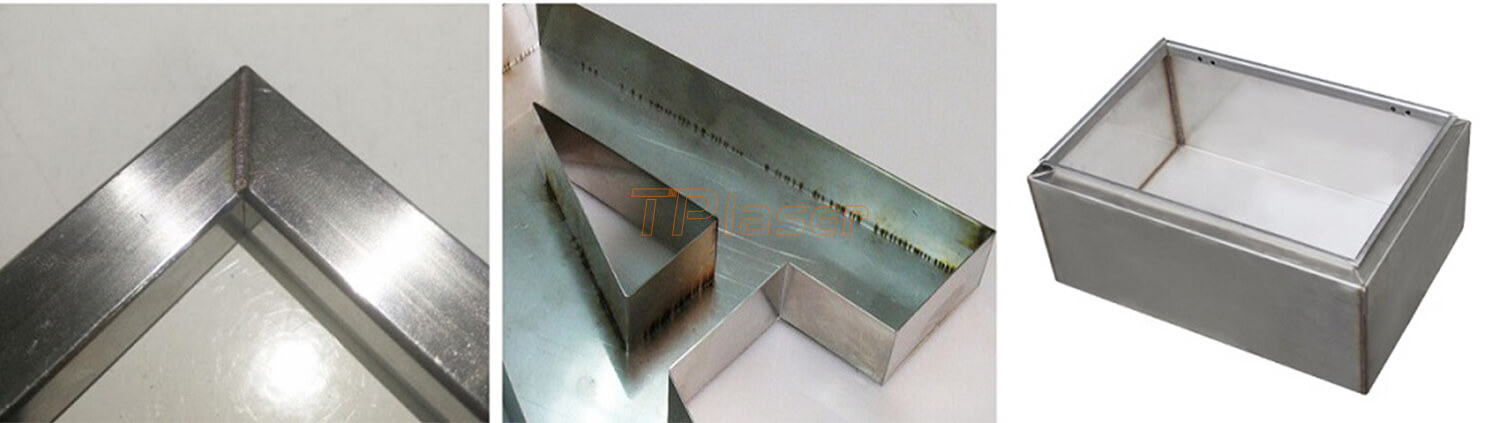

The key to hand-held welding is to realize the laser welding of long-distance, large-product workpieces, get rid of the limitation of the operation table’s stroke arrangement area, and the cold hazard range during welding is small, and it will not cause deformation, blackening, and imprints on the reverse side during work. And the welding depth is large, the welding is firm, and the melting is sufficient. It can not only complete the heat conduction welding, but also can continue deep penetration welding, welding, butt welding, stitch welding, sealing welding, seam welding, etc.

This kind of processing technology overturns the traditional working mode of laser welding machine. It has the advantages of easy use, beautiful and generous welding, faster welding speed, and no consumables. It is used in metal composites such as thin stainless steel plates, stainless steel plates, and galvanized steel plates. Material layer welding can well replace traditional argon arc welding machine, stainless steel plate, stainless steel plate, aluminum alloy plate and other metal composite material layer welding.

Advantages of Handheld Laser Welding Machine with Fiber Laser Beam

1.Wide welding coverage: The handheld laser welding machine head is equipped with 5-10M genuine optical fiber, which can get rid of the limitation of the console area, and can be welded outdoors and long-distance welding.

2.Easy to use and flexible: Handheld fiber laser welding machine is equipped with moving rollers, which is comfortable to hold, and can adjust the process anytime and anywhere, without specifying the process, free and flexible, suitable for various office environment scenarios.

3.A variety of welding methods: It can complete welding in any direction: stack welding, butt welding, overhead welding, flat fillet welding, internal fillet welding, diagonal welding, etc. Welding is carried out as standard. Complete welding in any direction. In addition, he can also perform laser cutting, welding and laser cutting can be switched at will, as long as the welding copper nozzle is changed to laser cutting copper nozzle, it is very convenient.

4.The welding effect is very good: Handheld laser welding machine is thermal arc welding. Compared with traditional welding, fiber laser welding machine has better energy and can achieve faster actual welding results. The welding area has less heat hazard, deep welding, and melting. Sufficient, strong and reliable, welding compressive strength reaches or even higher than the original material itself.

5.Welding does not need to be polished: After traditional welding, the welding points must be polished to ensure smoothness and not smoothness. The handheld laser welding machine just shows a lot of advantages in the production and processing effect: continuous welding, smooth welding without fish scales, beautiful and generous without scars, and less polishing process after the fact.

6.Welding without consumables: the welding work in most people’s memory is “right hand protective glasses, left hand clamp welding rod”. However, after having a handheld laser welding machine, welding can be carried out easily, which reduces the cost of raw materials in production.

7.There are several safety alarms. It is reasonable to move the power switch when the welding nozzle touches metal materials. After removing the product workpiece, it will automatically lock the light, and the power switch has the human body temperature and magnetic induction. The safety factor is high to ensure the safety of the employees during their work.

8.Labor cost saving: Compared with electric welding, the production cost can be reduced by up to 30%. The actual operation is simple and easy to learn, and the actual operation staff is not technically demanding. Ordinary employees can enter the post after a short period of learning and training, which can better complete the actual effect of high-quality welding.

Configurations of Handheld Fiber Laser Welding Machine

| Model | TPH-1000W |

| Laser source | Raycus |

| Laser power | 1000w/2000w/3000w |

| Cooling system | Water cooling |

| Working environment temperature range | 15~35 ℃ |

| Adjusted spot range | 0.1-3.0mm |

| Spot size | 0.2-3.0mm |

| Humidity range of working environment | < 70%No condensation |

| Working voltage | 220V,50/60hz |

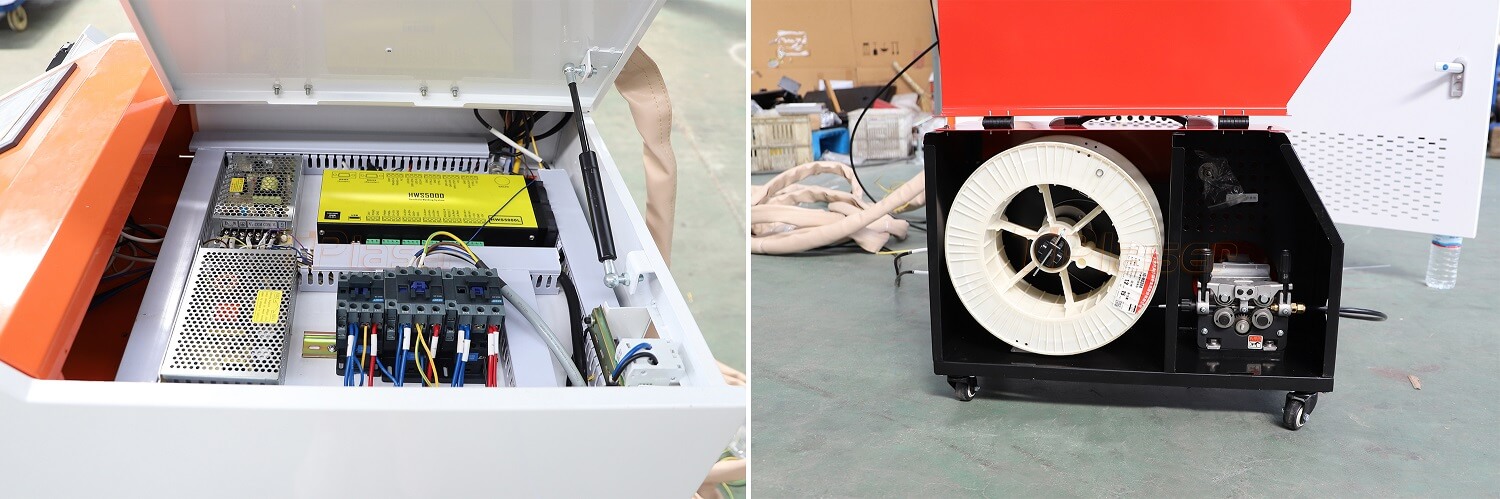

Details of Handheld Laser Welding Machine

Handheld Fiber Laser Welding Machine Features

1.Welding large metal advertising characters uses handheld welding heads to overcome the limitations of workbench space.

2.Weld small metal advertising characters fixed welding head, move characters to weld, easy to operate. The fixed welding head can be rotated universally, which overcomes the inconvenience of single-direction rotation of the traditional welding head.

3.The handheld fiber laser welding machine head is equipped with five meters of imported optical fiber, which is flexible and convenient to realize outdoor welding.

4.The operation mode of the hand-held welding gun can weld any part of the workpiece at any angle.

5.It can do dual-light path intelligent switching, and the energy distribution of time-sharing and light-sharing is even.

6.fiber laser welding machine suitable for all kinds of complex welding seams and spot welding of various devices

Handheld Laser Welding Machine Applications:

Handheld laser welding machine is mainly used in industries such as electronic components, auto parts, instrumentation, precision machinery, and communication equipment.

Applicable materials for handheld laser welder machine: rapid welding of stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized sheet, aluminum-plated zinc sheet, copper and other metal materials, as well as welding between certain dissimilar materials.

Comparison of handheld laser welding machine and argon arc welding machine

1.Energy consumption comparison: Compared with traditional arc welding, handheld laser welding machine can save 80% to 90% of electromagnetic energy, and production costs can be reduced by about 30%.

2.Comparison of actual welding results: Laser welding machine can be used to weld different steel and special-shaped metal materials. The speed is faster, the deformation is small, and the thermal hazard zone is small. Good-looking welding, leveling, no/less vent holes, zero pollution. The hand-held laser welding machine can carry out micro-opening parts and high-precision welding.

3.Comparison of after-the-fact process flow: low cold typing during laser hand-held welding, small deformation of the product workpiece, beautiful welding surface, no need or only simple solution (depending on the actual effect of the welding surface). The handheld laser welding machine can greatly reduce the labor cost of the huge grinding, polishing and smoothing process.