Product Introduction

Buyer's ReviewsFoam board cutting machines are more and more widely used, involving advertising, clothing, shoes and hats, automotive supplies, carpet sofas, gaskets, carton packaging, leather digital printing, decoration, aerospace, electronic equipment and many other industries.

Demonstration Video

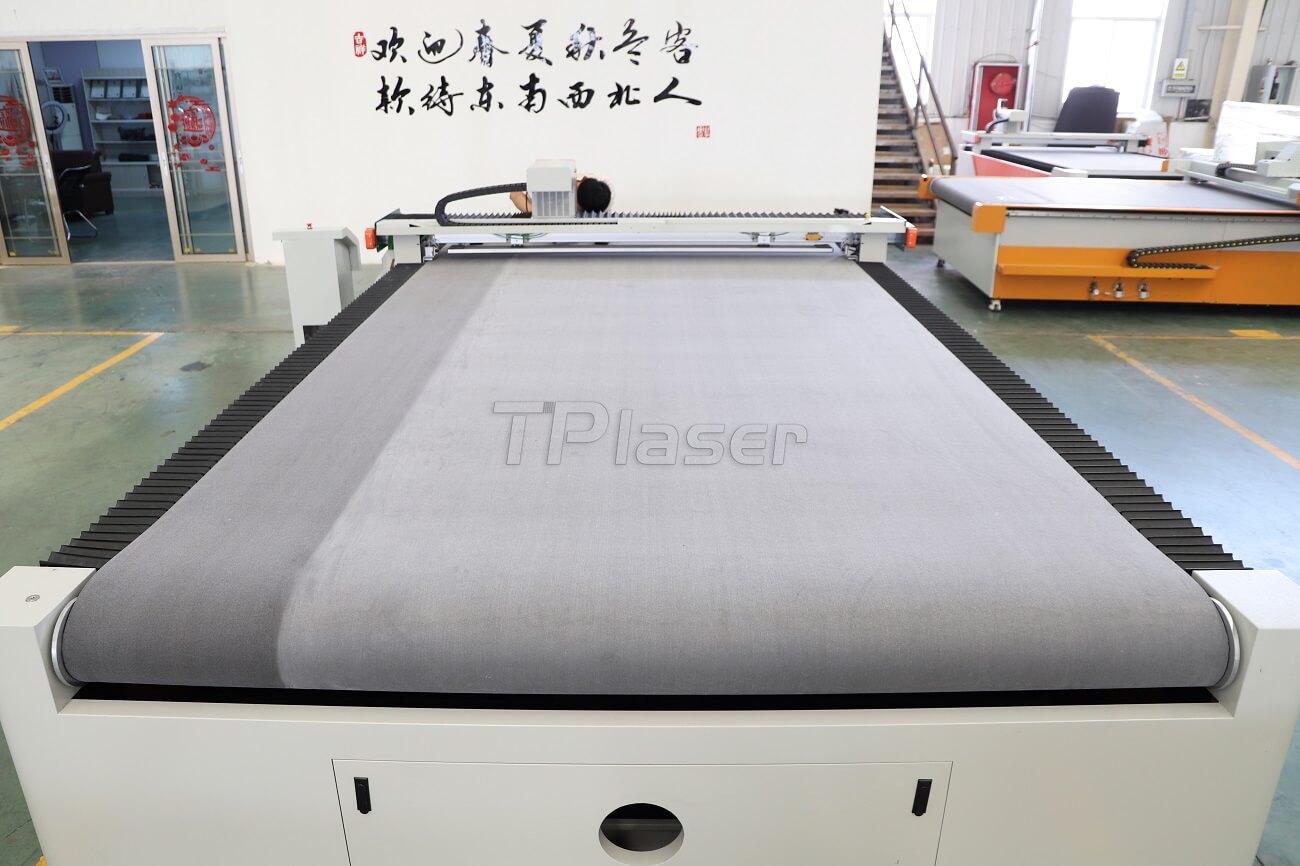

Product Descriptions

TPLaser foam board cutting machine is mainly aimed at special-shaped cutting of non-metal flexible materials. It adopts self-developed CAM cutting software and intelligent nesting typesetting software, and is equipped with vibrating knife, pneumatic knife, wheel cutter, creasing knife, drawing pen, milling cutter It can quickly complete various processes such as full cutting, half cutting, milling, punching, crease, marking, identifying contour cutting, etc., and solve the problem of special-shaped drawing cutting.

Why Choose Foam Board Cutting Machine?

1.Environmental protection, intelligent cutting machine cutting without odor, dust and pollution

1).Using a foam board cutting machine, high efficiency, fast response speed, and more in line with the environmental protection standards of modern enterprises, the cutting principle of the vibrating knife cutting machine is that the physical blade cutting achieves fast cutting with high-frequency amplitude.

2.Save time, material and labor

1). The template design is diversified, quick to use and time-saving.

2). The foam board cutting machine adopts intelligent typesetting software. It only needs to import the CAD drawings of the pieces to be cut into the typesetting software to implement automatic typesetting, which is fast and convenient for fool-like operations. The material utilization rate is as high as 90%, which can save a series of links in the middle. . A vibrating knife cutting machine can replace 5-8 cutting workers to make the enterprise more competitive.

3). Save labor costs (no need for proofing personnel to do die proofing manually), save a lot of time to invest in product design and development, so as to achieve a more perfect product

3.Provide a complete solution, fast response speed and high cutting precision

1). It can quickly solve the difficult dilemma of small batch production. For small batch product orders, the production can be completed directly on the foam board cutting machine.

2). The cutting precision is high, the automatic cloth cutting machine has an intelligent error compensation system, and there is 0 error in repeated cutting.

Specifications of Foam Board Cutting Machine

| Model | TPK1625/1825/2030 |

| Working size | Accept customization |

| Multifunctional cutting head | Replaceable vibrating knives, semi-penetrating knives, oblique knives, pressure rollers and other tools |

| Tool configuration | Various cutting tools, pressure wheel, pen, cross positioning laser |

| Security configuration | Highly sensitive infrared sensor (optional) |

| Moving speed | Up to 1200mm/s |

| Working speed | Up to 800mm/s (set according to different cutting materials) |

| Cutting material | EPS, foam, sponge, car floor seat cover, sofa cover, genuine leather, clothing fabric, corrugated paper, chevron board, kt board,etc. |

| Cutting thickness | Maximum 50mm (depending on different materials) |

| Material fixing method | High-power vacuum adsorption and intelligent partition |

| Repeatability | 0.01mm |

| Mechanical accuracy | 0.02mm |

| Transmission system | Steel wire timing belt, AC servo motor, linear guide |

| Control System | Dual 32-bit RISC core cpu + large-scale programmable logic array FPGA |

| Display method | Chinese and English LCD touch screen |

Details of Foam Board Cutting Machine

Samples of Foam Board Cutting Machine

Our Company

TPLaser adheres to the motto of “customer first, service first”. we believe in the spirit of enterprise“cooperation, win-win, appreciate and share “, and continue to attract top talents and precision laser technology to join us, TPLaser is a leading CNC equipment manufacturer in China and has launched 10 series products with an annual production capacity of 1,120 sets. With advanced CNC technology, perfect quality management system and convenient after-sales service in the network of mainland China and global markets.

If you are interested in any of our products or would like to discuss a custom order,please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.