Product Introduction

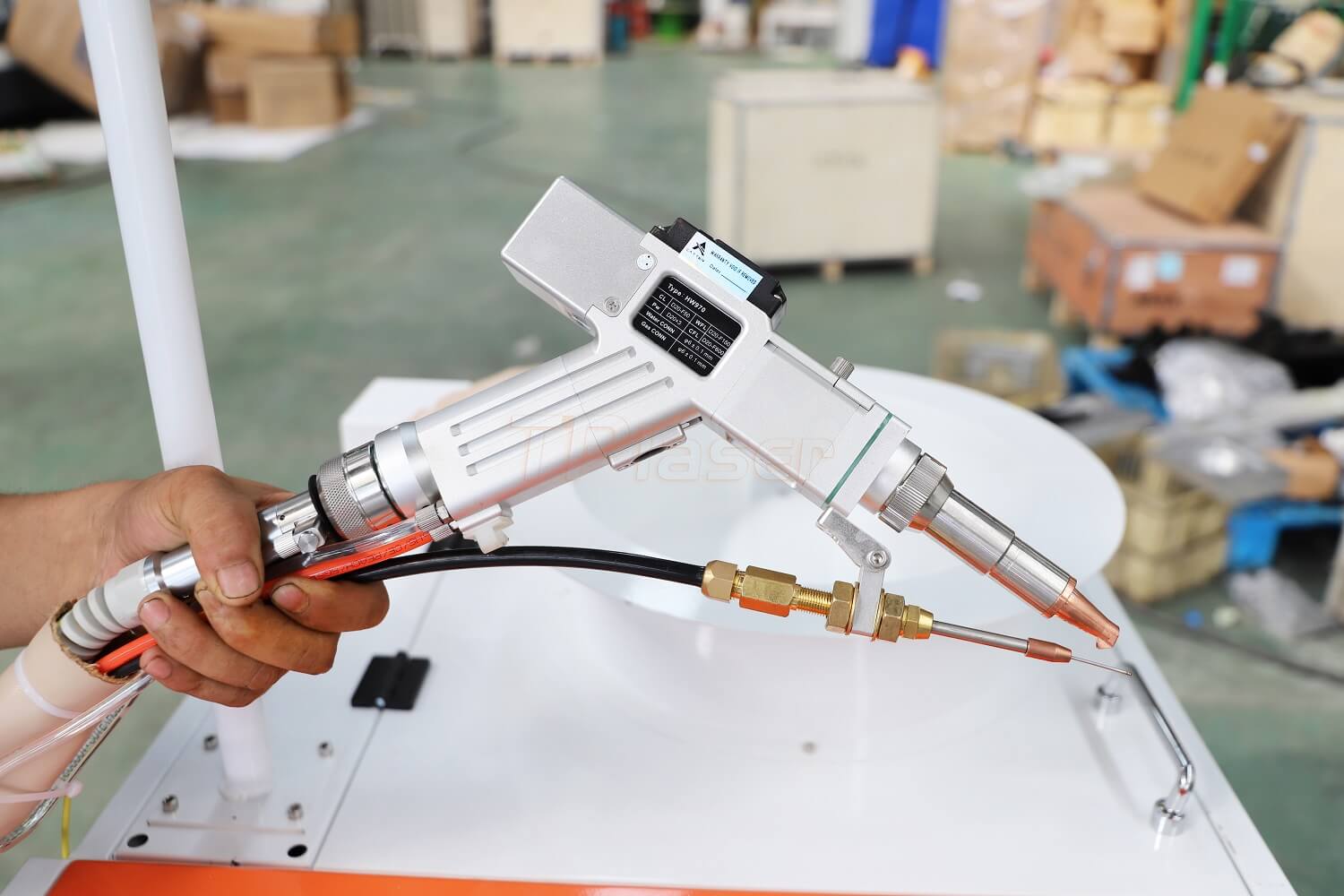

Buyer's ReviewsThe working mode of the fiber laser welding machine is hand-held welding, flexible and convenient, and the welding distance is longer. Replace the previously fixed light path with a hand-held welding gun. It is mainly used for laser welding of long-distance and large workpieces. The heat-affected area is small during welding, which will not cause work deformation, blackening, and traces on the back. The welding depth is large, the welding is firm, and the melting is sufficient.

Demonstration Video

Product Descriptions

Fiber laser welding machine: It is mainly composed of laser, welding system, hand-held laser gun and cooling system. Fiber laser has the characteristics of good beam quality, fiber output and high electro-optical conversion efficiency. It is mainly used for welding thin-walled materials and rapid welding. , The welding process is of heat conduction type, that is, the surface of the workpiece is heated by laser radiation, and the surface heat diffuses to the interior through heat conduction. By controlling the parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece is melted to form a specific molten pool.

Features of Fiber Laser Welding Machine

1.The internal design of the fiber laser welding machine is smart, and the good interactive control system expands the tolerance range of the processing parts and the width of the weld, solves the disadvantage of small spot, and the weld is formed better.

2.The shape is light, the body engineering design method is adopted, and the grip is comfortable; it is easy to control with one hand, and the operation is simple and easy to use.

3.The fiber laser welding machine has multiple safety alarms, and the light is automatically locked after the workpiece is removed, with high safety.

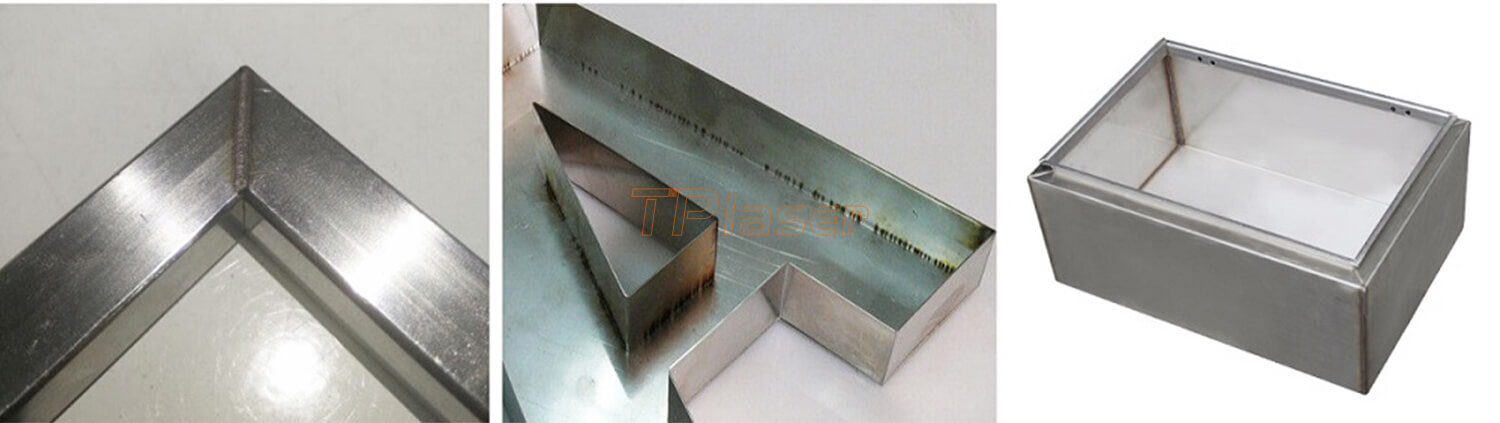

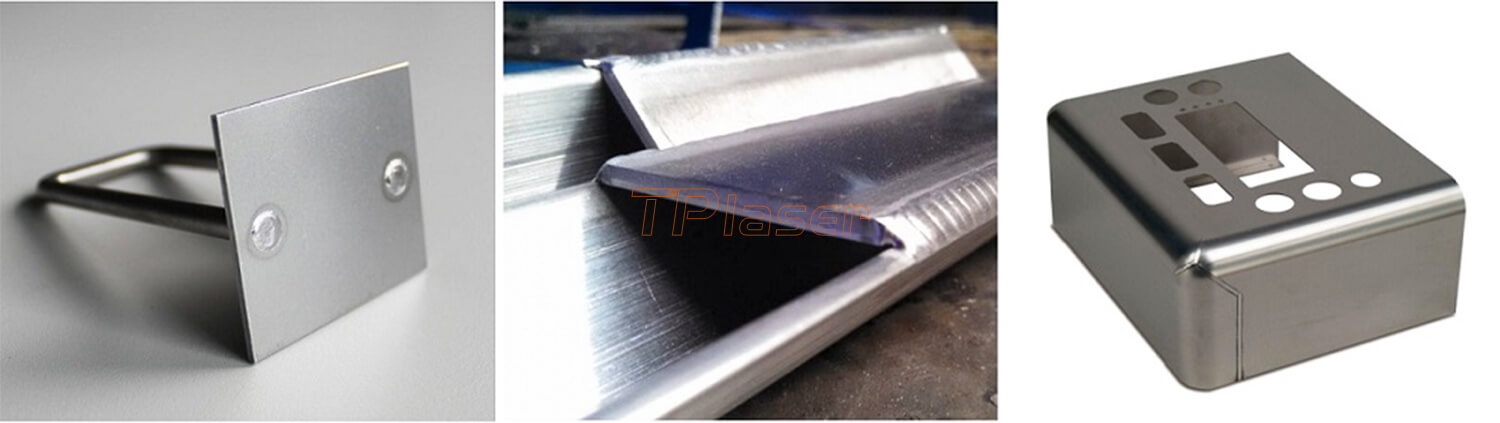

4.Beautiful welding seam, fast speed, no consumables, no welding marks, no discoloration, and no need for post-grinding.

5.Various angle nozzles can be configured to meet the welding needs of different products.

Applications of Fiber Laser Welding Machine

Fiber laser welding machine can be widely used in complex and irregular welding processes in cabinet kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home and other industries.

Advantages of Fiber Laser Welding Machine:

1.The fiber laser welding machine is relatively small, occupies a small area, and is very convenient and flexible.

2.The welding is basically not deformed, and it can be formed at one time.

3.The welded seam is more beautiful, there is no welding scar, no grinding is required, and it is very firm. 4. The safety of hand-held laser welding machine is relatively strong.

Specification of Fiber Laser Welding Machine

| Model | TPH-1500W |

| Laser source | Raycus |

| Laser power | 1000w/2000w/3000w |

| Cooling system | Water cooling |

| Working environment temperature range | 15~35 ℃ |

| Adjusted spot range | 0.1-3.0mm |

| Spot size | 0.2-3.0mm |

| Humidity range of working environment | < 70%No condensation |

| Working voltage | 220V,50/60hz |

Use of hand-held laser welding machine

1.Preparations before starting the machine

(1) Check the power supply of the laser welding machine and whether the water circulation is normal.

(2) Check whether the gas connection of the equipment in the machine is normal.

(3) Check that the surface of the machine is free of dust, spots, oil, etc.

2.Start

(1) Turn on the power and turn on the main power switch

(2) Turn on the water cooler, laser generator, etc. in sequence

(3) Open the argon valve and adjust the gas flow.

(4) Input the current work parameters to be executed

(5) Perform welding operation

3.Operating procedures

(1) Check whether each part of the welding machine is working normally.

Before welding, check whether all parts of the laser welding machine work normally. After the operation, check the welding machine and the workplace to eliminate hidden dangers and ensure safety and no accidents.

(2) Avoid fire caused by laser irradiation

Direct irradiation or strong reflection of the laser beam will cause combustibles to burn, resulting in fire. In addition, there are thousands to tens of thousands of volts of high-voltage electricity in the laser, which will be injured by electric shock. Therefore only trained personnel are allowed to operate the laser welding machine. The optical path system of the laser must be fully enclosed with metal to prevent direct irradiation, and the laser welding table should also be shielded to prevent the irradiation of radiation.

(3) Laser damage to eyes should be avoided

The power density of the laser used in laser welding machine welding is very high, and the beam is very thin, which can easily cause damage to people’s eyes and skin. Therefore, attention should be paid to eye protection during laser welding operations. On-site operators must wear laser-specific protective glasses.

(4) Laser burns to the skin should be avoided.

Directly irradiating the skin with the laser will cause burns to the skin, and the long-term effects of diffuse reflection will also lead to skin aging, inflammation and skin cancer lesions of the operator. Field operators need to wear overalls to reduce the impact of diffuse reflection.