Product Introduction

Buyer's ReviewsAutomatic gasket cutting machine is suitable for asbestos, graphite, rubber, silicone and other materials. It has professional software developed for the gasket industry. It has the characteristics of high cutting accuracy, efficiency, no sawtooth, no burr, smoothness, and good consistency. Simple operation and low failure rate.

Demonstration Video

Product Descriptions

Automatic cnc gasket cutting machine is suitable for cutting graphite, graphite metal gasket, asbestos, rubber, silica gel, cork, PTFE and other sealing materials.

Automatic cnc gasket cutting machine adopts data import and cutting, no need for mold, high cutting precision, good cutting edge effect, no burr, the self-developed nesting system can save more than 20% of material compared to manual typesetting.

Features of Automatic CNC Gasket Cutting Machine

(1) Computer numerical control, automatic cutting, 7-inch LCD industrial touch screen, standard Delta servo

(2) Automatic cnc gasket cutting machine adopts a high-speed spindle motor, and the speed can reach 18,000 rpm

(3) Positioning at any point, cutting through (vibrating knife, pneumatic knife, round knife, etc.), semi-penetrating (basic function), indentation, V-groove, automatic feeding, CCD positioning, pen writing (optional function)

(4) Automatic cnc gasket cutting machine adopts high-precision Taiwan Hiwin linear guide, with Taiwan TBI screw as the core of the machine base, to ensure accuracy and accuracy

(5) Japan Omron optocoupler

(6) The material of the cutting blade is Japanese tungsten steel

(7) Regin high-pressure vacuum pump to ensure accurate adsorption and positioning

Specifications of Automatic CNC Gasket Cutting Machine

| Model | TPK2030 |

| Working area | 2000*3000mm |

| Cutting Speed | 200-2000mm/s |

| Positioning accuracy | ±0.01mm |

| Cutting Thickness | According to material |

| Feeding method | Automatic feeding system |

| Safety devices | Infrared induction |

| Support format | DXF, AI, PLT, CDR, etc. |

| Motor | Servo motor |

Parts Detail of Automatic Gasket Cutting Machine

Application of Automatic Gasket Cutting Machine

Applied Materials:

Automatic gasket cutting machine can be widely used for non-metal flexible materials not exceeding 60mm, including: gasket gaskets, rubber, silicone, genuine leather, leather, composite materials, corrugated paper, car mats, car interiors, cartons, color boxes , Soft PVC crystal pad, composite sealing ring material, shoe sole, cardboard, gray board paper, KT board, pearl cotton, sponge, plush toys, etc.

Application industry:

★Apparel, luggage, handbag and shoe industry are used for cutting fabric and leather

★Toy industry cutting composite materials

★Advertising industry cutting KT board, etc.

★Cut crystal table mats, sofa covers, non-slip mats, etc. in the home industry

★Auto industry cutting car seat covers, wire ring foot pads, etc.

★The packaging industry is used for cutting corrugated paper, etc.

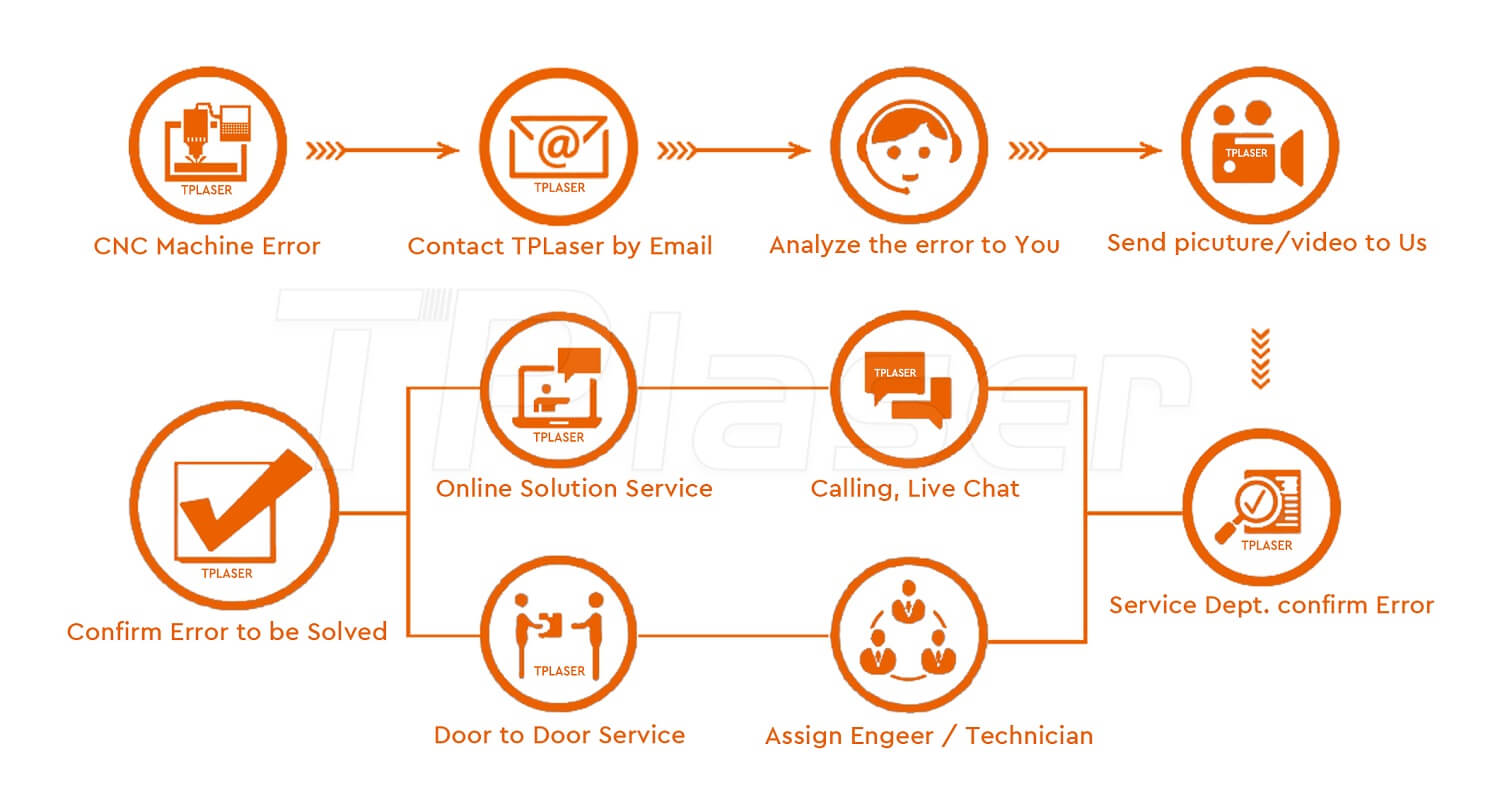

After Service of Automatic CNC Gasket Cutting Machine

1.We will supply automatic cnc gasket cutting machine with training video and user’s manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

2.You can come to ourautomatic gasket cutting machine factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

3.Our engineer will do a door-to-door instruction training service at your local site.

Our Company

TPLaser adheres to the motto of “customer first, service first”. we believe in the spirit of enterprise“cooperation, win-win, appreciate and share”, and continue to attract top talents and precision laser technology to join us, TPLaser is a leading CNC equipment manufacturer in China and has launched 10 series products with an annual production capacity of 1,120 sets. With advanced CNC technology, perfect quality management system and convenient after-sales service in the network of mainland China and global markets.

If you are interested in any of our products or would like to discuss a custom order,please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.